Fiberglass epixy

Have used fiberglass w West system epoxy on two boats built. One a cosine Wherry which is closest to what you query.

First: make sure the wood is clean (bare), and fill any large defects. Then let it dry! After finish sanding and careful vacuuming, lay out your fiberglass and ( tricky part) try to keep it as flat and tight on the wood as possible.

Second: Buy, or make a roller ( I’ve made several out of heavy metal wire with metal washers ( alternating large and medium) , and have it ready when you wet the glass. Then roll carefully to not trap air pockets ( which you will), and when you do, go back to that area ( means you lift the glass beyond the defect off and start over) rolling in single direction and care to get a feel for applying just the right amount of epoxy to ensure the mat is completely wetted will take some time, but you’ll get there.

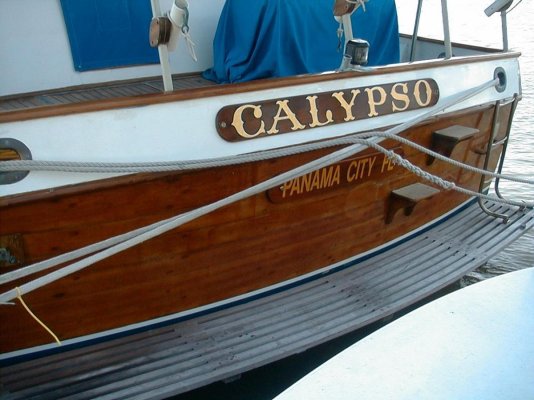

3: Sand to at least 120, ( I prefer 220) then Varnish with your preferred UV varnish ( I like z-spar), and you will have a very long lasting result. After more than 30 years on that edge planked Wherry not a single problem arose.

The look of varnished wood, but not the upkeep. I revarnish every few years depending on use, but the system described has worked like a charm for me. Hope this may be of some help. Good luck!