BrisHamish

Senior Member

- Joined

- Apr 7, 2016

- Messages

- 223

- Location

- Australia

- Vessel Name

- Beluga

- Vessel Make

- Grand Banks 46eu 2006 hull#289

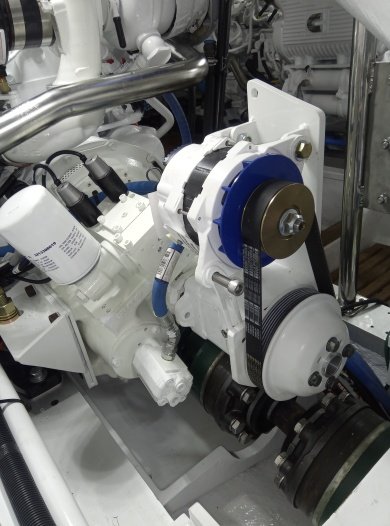

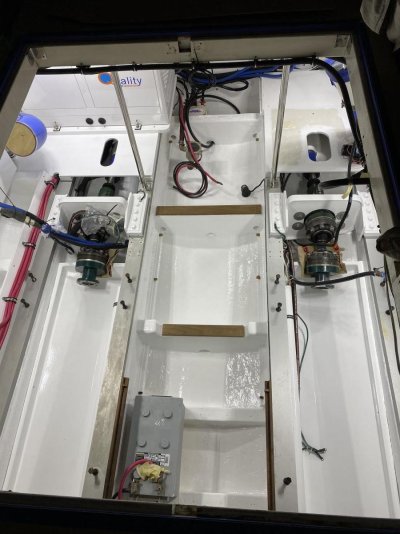

So for those who might be interested, I will post a series of short threads and photos depicting the repower of our 2006 GB46eu last year.

The previous CAT C7s had had aftercooler failures during the tenure of the previous owner in about 2008, and the consequences of salt water having gotten into the engine cores came home to roost in 2020 when the port engine developed a ‘knock’ in no 1 cylinder, leading us (eventually, after eliminating ‘easy’ causes such as injectors) to do a borescope inspection of the internal of both engines. What we found wasn’t pretty.

Glossing over the horror/heartache (which lasted quite a while), I sold both CAT engines with full disclosure to guy who wanted to completely rebuild them, and after taking competing bids for new engines from CAT, Cummins, John Deere, Nanni, Volvo and Yanmar, we chose Cummins QSC 8.3 at 550hp.

The new engines are v smooth and smoke free, and use very slightly less fuel that the CATs they replace even though they develop more power and torque.

Photos follow.

H.

The previous CAT C7s had had aftercooler failures during the tenure of the previous owner in about 2008, and the consequences of salt water having gotten into the engine cores came home to roost in 2020 when the port engine developed a ‘knock’ in no 1 cylinder, leading us (eventually, after eliminating ‘easy’ causes such as injectors) to do a borescope inspection of the internal of both engines. What we found wasn’t pretty.

Glossing over the horror/heartache (which lasted quite a while), I sold both CAT engines with full disclosure to guy who wanted to completely rebuild them, and after taking competing bids for new engines from CAT, Cummins, John Deere, Nanni, Volvo and Yanmar, we chose Cummins QSC 8.3 at 550hp.

The new engines are v smooth and smoke free, and use very slightly less fuel that the CATs they replace even though they develop more power and torque.

Photos follow.

H.

Attachments

-

FAC5E1CD-0256-4259-87D7-814F7951C262.jpeg154.6 KB · Views: 68

FAC5E1CD-0256-4259-87D7-814F7951C262.jpeg154.6 KB · Views: 68 -

95A2098E-2292-4FA6-958F-3E014211DE9D.jpeg158.5 KB · Views: 61

95A2098E-2292-4FA6-958F-3E014211DE9D.jpeg158.5 KB · Views: 61 -

11D74776-DB6C-4DA6-B7E9-8736F07F833D.jpeg157.8 KB · Views: 64

11D74776-DB6C-4DA6-B7E9-8736F07F833D.jpeg157.8 KB · Views: 64 -

8CA16DC7-C4EF-46D6-BDC3-1114E93F9FA9.jpeg154.8 KB · Views: 54

8CA16DC7-C4EF-46D6-BDC3-1114E93F9FA9.jpeg154.8 KB · Views: 54 -

Hamish 1.jpg176.2 KB · Views: 60

Hamish 1.jpg176.2 KB · Views: 60 -

Hamish 2.jpeg131.2 KB · Views: 68

Hamish 2.jpeg131.2 KB · Views: 68

Last edited by a moderator: