koliver wrote:

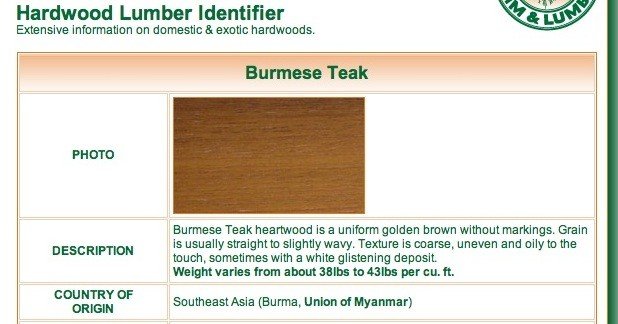

So, what really is the difference between Burmese and any other?

Originally, Burmese teak was the name of old-growth teak grown in Southeast Asia.* It grew all over the place, not just Burma, but it acquired the Burmese name because I assume most of the harvest came from there or it was the easiest name to say, I don't know.* Like "California" avocados--- all you need to grow them anywhere on the planet are the right conditions.

Remembering back to my forestry major days, grain and figuring within a given tree are the result of the conditions the tree was subjected to as it grew.* Within a specific tree you will get a variety of grain configurations and how this grain appears in the finished plank (or veneer) will depend on how the log is cut up.* An advantage of using wood with a straight, uniform grain is that the problem of matching adjacent pieces of wood is minimized.* It's boring as hell, but it all has the same look, which means that matching grain, figuring, color, etc. is not so critical and thus reduces the cost of making the boat or furniture or whatever.

You can get uniform, straight grain planks out of many old growth trees: it all depends on how the mill cuts it.

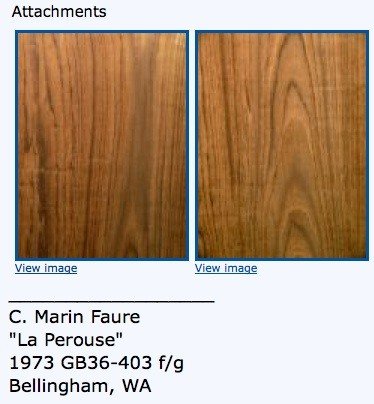

Some yards and wood suppliers will buy entire logs of a particular kind of wood--- oak, teak, etc.--- and cut the log into parallel planks.* The orientation of the planks is never changed but spacers are placed between each plank for air circulation and the wood is allowed to dry naturally.* By storing the planks oriented exactly the same as they were when they were part of the tree, wood cut from the top of one plank will have the same color, grain, and figuring of wood cut from the bottom of the next plank.* So on furniture, cabinetry, etc. you can have beautiful figuring and grain and the pieces will all have the same characteristics.

Some boatyards, like American Marine, that started in wood tended to go for the more interesting figuring that was characteristic of old-growth teak, be it from Burma, Thailand, or wherever.* Same as furniture makers.* For example, on the backs and bottoms of the drawers and cabinetry in our boat, the various pieces of wood have inked markings on them delineating the hull number and the number of the individual piece.* This was done to keep the characteristics of the wood consistent in the boat and in that particular cabinet.* So the sections of the hanging cabinet in our galley, for example, are labeled "403-1", "403-2", "403-3" and so on.* This ensured that the color and grain of the wood would match at corners and so on.

But in more recent years as this wood became more and more rare and more and more regulations were placed on its harvest and sale, the move was made to plantation teak.* One of the advantages is that because the wood from plantation teak is pretty much uniform in color and grain, it all looks about the same no matter what particular tree it came from., where it came from within the tree, or even where it was grown.

I've used a few pieces of plantation teak in our boat before I found a good source of old-growth teak in Washington, and it doesn't match at all.

A parallel to the teak situation can be found in the walnut situation.* It used to be that almost all gunstocks were made of walnut.* Even a cheap Sears & Roebuck rifle often had beautiful wood in the stock although it usually had a lousy finish on it.* But today, unless he rifle is very high end or has a composite stock, the wood stocks look like crap.* That is because old-growth walnut has become like old-growth teak--- staggeringly expensive.

*