BusterBrown,

Just for S and G

I'm sure this doesn't apply to your engine at all- but am going to post a couple of pictures and hopefully a short video of a #1 piston we pulled today in a mid '80s Hyster forklift with a 192 Ford Industrial GAS 4 cylinder engine. Compression was 130-150 all 4 holes.

The customer does most of their own maintenance (or non maintenance) and none of my guys actually ever remembers hearing it run in the past. The engine had seized- and the owner and I agreed to lift the machine, pull the pan and determine if it could be repaired low dollar, as in polish the rod journal and roll in new bearings. Turned out #1 was seized, and loosening the rod cap allowed us to turn the crankshaft. The rod bearing inserts had not "spun" inside the connecting rod, and the rod journal was actually in pretty good shape. It was a little puzzling- the oil pump feeds from the center of the crankshaft yet #4 rod bearings and the rear main journal did not look oil starved (we assumed it had run out of oil). Damn this is a long story. My thumb's getting tired.

Anyway, Polish one rod journal, new rod/ main bearings- torqued, new lube filter and fill with oil. Started.

The engine had a definite knock. Pulling the #1 plug wire (effectively taking the compression load off of the cylinder) did not quiet it.

Holy cow- I think we have some "piston slap" going on!!

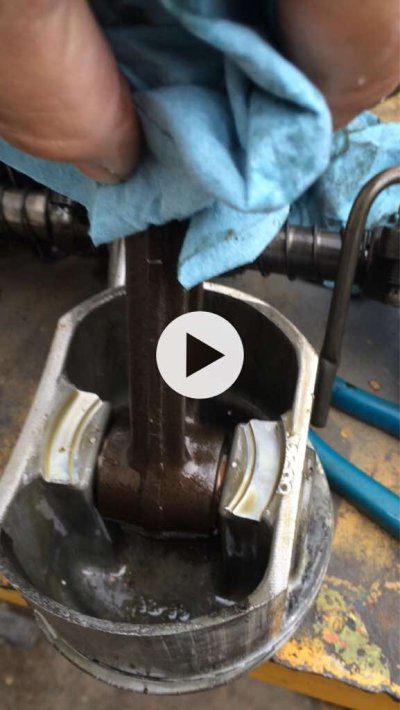

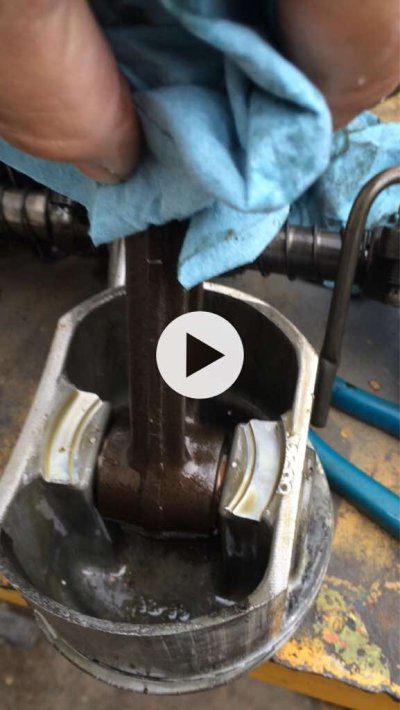

My guy Ben pulled the pan again, removed the head, and this is what we saw. Ugly...

We have piston gaulding (imagine THAT oil sample), I suspect piston slap, and extreme wear on the connecting rod piston pin bushing (video if it makes it). I'm not sure why the piston originally began to seize, but I believe the rod bearing and wrist pin failures were a result of it. Thought some of you might get a kick out of the pictures. Sorry, no luck with video so grabbed a screen shot.

1983 Present 42 Sundeck

Twin Lehman 135's