dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,555

- Location

- Gig Harbor, WA

- Vessel Name

- Kinship

- Vessel Make

- 2010 North Pacific 43

And on the other end, I thought you were going to feed the DC system through the DC panel, either through a sub breaker or through the main panel breaker. Your wire should be big enough for even the main breaker (often 50-60 amps). But maybe if you are feeding the main breaker, you want a disconnect and that 30A should work fine.

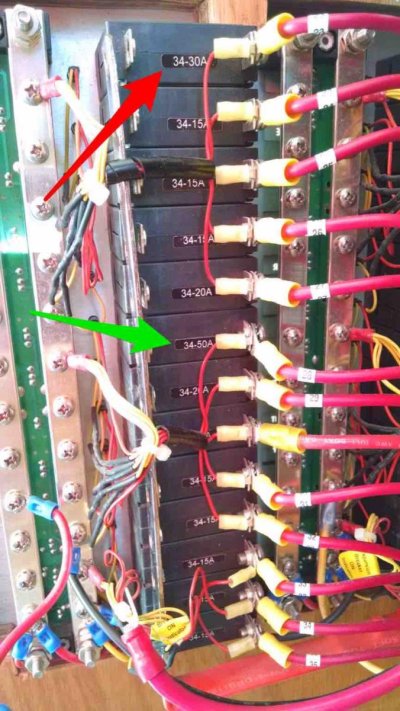

I was able to get down to the boat today for a couple hours to try and figure out exactly where I could run wire. I also took a closer look at my DC panel in the Pilothouse and found an unused breaker. It was originally for a water maker than the PO had installed and then removed after finding he just didn’t use it. That breaker is a 50amp breaker and the breaker for the panel as a whole is 100amp.

So if I was to take the positive feed from the controller and connect it to the 50amp breaker where the output for the water maker was, then that should back feed the battery as long as the breaker is on. I think I like this idea better than adding another surface mount breaker.

I ran a small line where I am going to have to run the 10 AWG wires from the panel on the pilothouse roof to the controller which will be behind the DC panel. That should make it easier to run the wires later.

Here is a stupid electrical question. How big a wire do I need from the controller to the 50amp breaker? I believe the idea is that the breaker needs to protect the wire. I think the panel has a 6 AWG wire that runs from the panel for about 3’ to the positive bussbar where it connects to a 70mm cable which runs to the battery. That would make sense since the panel breaker is a 100amp breaker. For a 50 amp breaker, what would be the largest wire that I would want to use to run the 3’ from the controller to the breaker? I would tend to use a 10 AWG wire, but am I correct that a 50 amp breaker would protect a 12 AWG wire and therefore would also provide plenty of protection for a 10 AWG wire.

Dang I hate being so dense!