I have just finished a similar exercise on my boat. First, the cables between the upper and lower stations were not adjusted well. Also, the adjustable end stops for the levers on the Morse controls were stopping travel.

I disconnected the cable from the injector pump on the engine (pull back the cylindrical sleeve, compressing the spring, and the end fitting can be lifted off the ball on the injector pump lever.

Disconnecting the cable at the engine allows you to adjust the levers at the (in my case) two stations. I also backed off the end stop screws on both Morse controls. I then got a lot more angular movement on the Morse levers. Also, I got the movement to be the same on all 4 levers (throttle up and down, port and stbd).

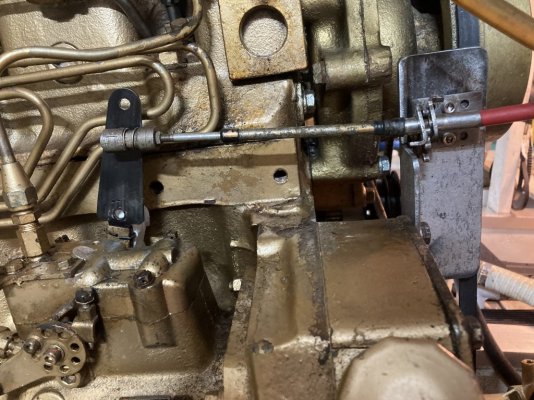

I then went to the engine and observed the position of the cable end for both extremes of lever travel and compared this with the injection pump lever at idle and WOT positions. On my engines (JD6404) the injection pump lever has a spring feature that allows the lever to be pushed (or pulled) beyond the idle and WOT positions without damaging the lever - so there is no risk of the Morse lever overloading the injection pump lever if the Morse travel stops are not correctly set.

You can adjust the action of the cable end at 3 places:

1 Cable end at the pump - disconnect the cable end from the ball, loosen the jam nut and rotate the cable end on the cable thread. Make sure you have at least about 1/4" of thread engaged into the cable end. Reapply jam nut when finished.

2 Cable end at the Morse control. Have to pull a cotter pin and rotate the end fitting as above. Pulling the pin is a real fiddle. It is also possible to change the total travel of the cable by putting the end fitting in a different hole in the Morse control, but that is getting to be a more serious change.

3 Moving the cable jacket clamp at the engine. This is a more drastic, and more coarse adjustment option.

When finished adjusting, you can set the Morse lever travel stops at (I suggest) the lower station.

On my boat I also increased the length of the injection pump lever arms in order to get more angular movement on the Morse controls from idle to WOT, but I won't go into that here.