Capthead

Guru

- Joined

- Mar 17, 2013

- Messages

- 956

- Location

- USA

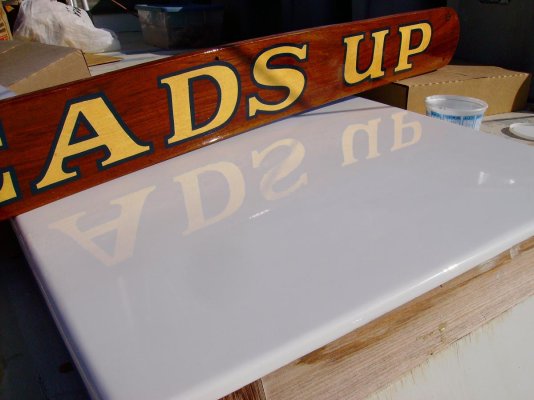

- Vessel Name

- Heads Up

- Vessel Make

- Grand Banks 42 Classic

Back in the 90's I was looking for a longer lasting varnish and happened upon a varnish used by Riva Yachts. Riva

They make the old style mahogany runabouts that are all varnished and they say it lasts 10 years. They also make large yachts and the teak has the same varnish and longevity. I soon found they sold the varnish they used and labeled it Rivali. It is sold as three steps and two are two part varnishes with different thinners.

They didn't have instructions and I had just come from several microsoft windows classes and found their application instructions by snooping their web page. I printed it and bought their two, two part varnishes and thinners. That was close to 400 back then but I thought worth it because sanding and varnishing three times a year all the teak on a GB 42 was taking too much time from my drinking habit.

I'll give you a run down on how this works. I know I'll get feedback, now that I've experienced the oil thing, and some will say it isn't so. lol just joking here.

Teak is wood with natural oils and that has to be addressed if you want a long term bonding with varnish and teak. First, sand the wood to a clean surface free of dirt. Then sand with 100 grit sand paper along the grain and that opens the grain for better penetration.

Then, I added this, I take the brush accessory on my vacuum and vacuum off all dust and wood particles. Now you can see open clean wood.

Now, put thick gloves on and get a stack of clean white rags and a can of MEK. Pour the mek on the teak and wipe it off. Repeat this until you get a clean rag and move over the entire teak cleaning it good. This removes the surface oils and fine sanding dust. If you don't do this step, don't expect a lasting bond.

They looked at varnish and teak at the molecular level and determined that tung oil based varnish made the best bond which is spar varnish. I used Captains and the first coat needs to be a 50/50 thinned coat. It will dry in a few hours and you can go back with a second coat of 30% thinned spar varnish. That's probably a day there.

The next day do a third and fourth coat and drop thinning to 25% and 20% respectfully.

Now you have 4 coats and the grain is visible and looks large. You haven't sanded between coats. If you sand and break through this coat to bare wood, you'll have to start over. This is the sealing coat and it should be sealed good.

The middle coating system is a polyester based varnish and there are now several companies that make it. There isn't any UV inhibitors in this. It's strictly for build up.

I take the 3M scrubbers/scratchers that are off red like maroonish. They scratch deep into the grain and that's what you need here. Scratch until there is no shine appearing but don't get into the wood. The two part is mixed and let set to combine then brush a coat on. It dries so fast that when I did my rails I was on one side, wife the other, we met at the transom cap rail and when we went back to the bow I could place my hand on the rail ans apply full pressure and it was dry. I could do 4 coats a day.

Pull all tape every day. This stuff builds fast and will leave an edge so always pull the tape. The next day, sand it with 220 and get most of the grain to disappear. Just be careful not to break through. After taping off, repeat 4 more coats.

Now you are ready for the top coat. Sand again with 220 and all grain should be gone. It should be smooth and pretty. The top coat is really a clear LP with a hue amount of UV inhibitors. It brushes on like butter. When you apply it, look back in 15 to 30 seconds all brush strokes disappear. It will look sprayed.

I buy a $20.00 or so badger brush that is made for varnish. Paint brushes have longer bristles and you will drip and run with them. Find the shorter more tapered varnish brush for this. You will have to toss it after use. I used everything to clean a few of them. Toss it. It's not worth the hassle.

Between coats sand with 320. Between the second and more I use the 3m instead of 320.

I like three to four top coats. It's done then. Always remove tape each day.

In four or five years, you can sand with 320 and apply a new top coat.

Places where it breaks through can be patched but always do the system and it will look like nothing happened afterward.

Rivali is no longer available but the company that made it still sells it. Stoppini is the brand. Here is a link in Europe. http://www.nautimarketshop.com/shop/en/producer/157/Stoppani.html

I think there is a supplier in Seattle. I had his number and I'll try to find it. It's amazing stuff.

Today, there are other brands selling LP and polyester varnishes so duplicating this system should be easy.

They make the old style mahogany runabouts that are all varnished and they say it lasts 10 years. They also make large yachts and the teak has the same varnish and longevity. I soon found they sold the varnish they used and labeled it Rivali. It is sold as three steps and two are two part varnishes with different thinners.

They didn't have instructions and I had just come from several microsoft windows classes and found their application instructions by snooping their web page. I printed it and bought their two, two part varnishes and thinners. That was close to 400 back then but I thought worth it because sanding and varnishing three times a year all the teak on a GB 42 was taking too much time from my drinking habit.

I'll give you a run down on how this works. I know I'll get feedback, now that I've experienced the oil thing, and some will say it isn't so. lol just joking here.

Teak is wood with natural oils and that has to be addressed if you want a long term bonding with varnish and teak. First, sand the wood to a clean surface free of dirt. Then sand with 100 grit sand paper along the grain and that opens the grain for better penetration.

Then, I added this, I take the brush accessory on my vacuum and vacuum off all dust and wood particles. Now you can see open clean wood.

Now, put thick gloves on and get a stack of clean white rags and a can of MEK. Pour the mek on the teak and wipe it off. Repeat this until you get a clean rag and move over the entire teak cleaning it good. This removes the surface oils and fine sanding dust. If you don't do this step, don't expect a lasting bond.

They looked at varnish and teak at the molecular level and determined that tung oil based varnish made the best bond which is spar varnish. I used Captains and the first coat needs to be a 50/50 thinned coat. It will dry in a few hours and you can go back with a second coat of 30% thinned spar varnish. That's probably a day there.

The next day do a third and fourth coat and drop thinning to 25% and 20% respectfully.

Now you have 4 coats and the grain is visible and looks large. You haven't sanded between coats. If you sand and break through this coat to bare wood, you'll have to start over. This is the sealing coat and it should be sealed good.

The middle coating system is a polyester based varnish and there are now several companies that make it. There isn't any UV inhibitors in this. It's strictly for build up.

I take the 3M scrubbers/scratchers that are off red like maroonish. They scratch deep into the grain and that's what you need here. Scratch until there is no shine appearing but don't get into the wood. The two part is mixed and let set to combine then brush a coat on. It dries so fast that when I did my rails I was on one side, wife the other, we met at the transom cap rail and when we went back to the bow I could place my hand on the rail ans apply full pressure and it was dry. I could do 4 coats a day.

Pull all tape every day. This stuff builds fast and will leave an edge so always pull the tape. The next day, sand it with 220 and get most of the grain to disappear. Just be careful not to break through. After taping off, repeat 4 more coats.

Now you are ready for the top coat. Sand again with 220 and all grain should be gone. It should be smooth and pretty. The top coat is really a clear LP with a hue amount of UV inhibitors. It brushes on like butter. When you apply it, look back in 15 to 30 seconds all brush strokes disappear. It will look sprayed.

I buy a $20.00 or so badger brush that is made for varnish. Paint brushes have longer bristles and you will drip and run with them. Find the shorter more tapered varnish brush for this. You will have to toss it after use. I used everything to clean a few of them. Toss it. It's not worth the hassle.

Between coats sand with 320. Between the second and more I use the 3m instead of 320.

I like three to four top coats. It's done then. Always remove tape each day.

In four or five years, you can sand with 320 and apply a new top coat.

Places where it breaks through can be patched but always do the system and it will look like nothing happened afterward.

Rivali is no longer available but the company that made it still sells it. Stoppini is the brand. Here is a link in Europe. http://www.nautimarketshop.com/shop/en/producer/157/Stoppani.html

I think there is a supplier in Seattle. I had his number and I'll try to find it. It's amazing stuff.

Today, there are other brands selling LP and polyester varnishes so duplicating this system should be easy.