Faith

Member

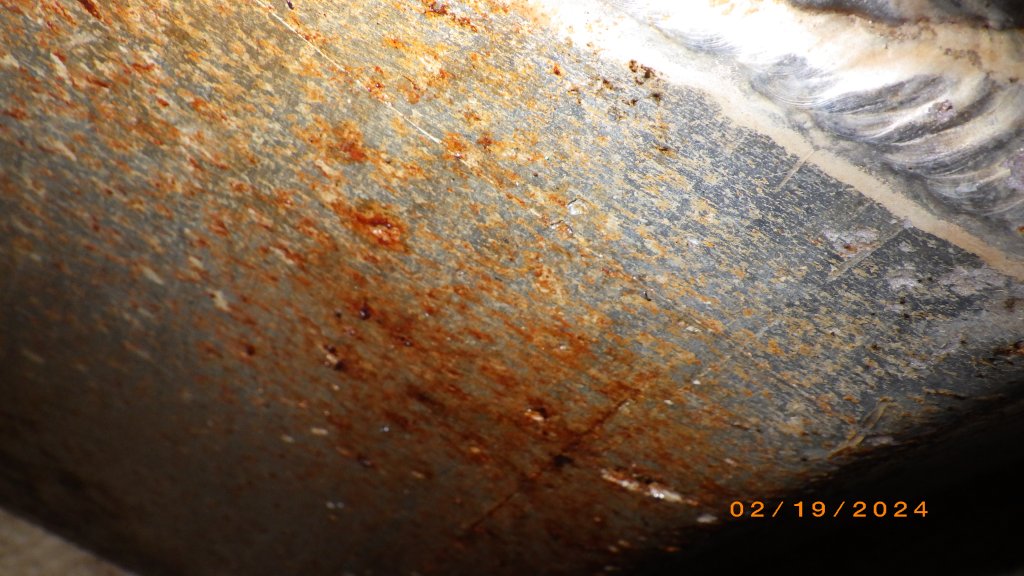

I had a survey done on a 2008 Mainship 34 Pilot II and the surveyor snapped a photo of a fuel tank with pits and rust on it. How big of a deal is this? He recommended that the buyer remove the 2 Yanmar diesels and find a new fuel tank which would be dificult because Mainship is ourt of business. Other people said it's not that big of a deal and would cost about 4 k for the tank, not sure about the labor (much more $ I'm sure). Surveyor said to me privately, if it was his boat he'd put some type of coating over it and monitor it.

Any thoughts or recommendations? Trying to get a replacement cost mainly. Thank you!

Thanks!

Any thoughts or recommendations? Trying to get a replacement cost mainly. Thank you!

Thanks!