twistedtree

Guru

This thread is to continue a discussion about using PLCs (Programmable Logic Controllers) in boats that started elsewhere as a side discussion. The relevant posts have been moved here so the discussion can continue without distracting from the other thread.

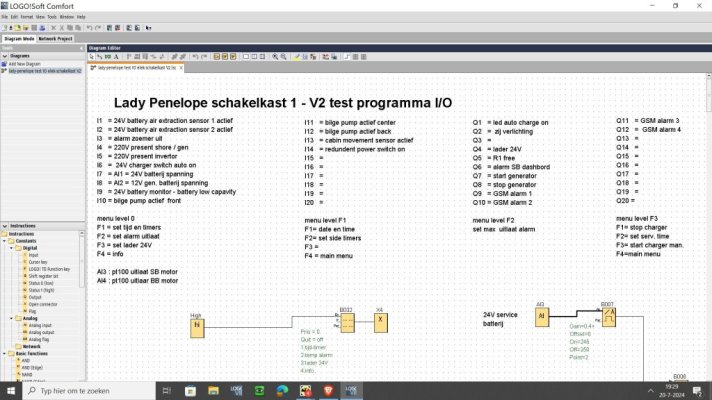

Because it's so reliable and well proven, I'm comfortable using PLCs, modbus, etc for controlling stuff on the boat, where I'm not comfortable using N2K for that. So my PLC/Modbus system monitors all my AC power sources (shore cords and generators), detects power and automatically connects the load panels (inverter, non-inverter, and HVAC loads), automatically controls the isolation transformer boost switch for dealing with 208 vs 240V shore power, and my new favorite - automatically adjusts the VIctron Inverter input load limit based on the capacity of the power source, and what other loads are connected. So the only manual operation is to plug/unplug shore cords, and start/stop generators, and the system does all the rest, assuming I have it in Auto mode. It can all be controlled manually too. And it even does generator autostart when the batteries drop below a set point. It's nice to know that I can leave the boat and if the shore power fails, the inverter will keep everything running. And if the batteries get low, the generator will recharge them. And when shore power is restored, everything will switch back. I know a lot of people don't like automation, but for me it comes down to on simple question. Is it reliable? Automation that works is awesome, and automation that doesn't work sucks. So far this all works.

The Modbus stuff is actually working quite well. I primarily use it for power monitoring and control, and it does that very well. I also export some data on N2k for display on N2KView for convenience. Programming PLCs and HMIs is positively stone-age, along the lines of 1980 BASIC programming. But programs are inherently pretty simple, so it works, and that's the best part. You turn it on, and a few years later it's still running just like the day you turned it on. I've had no issues at all with modbus compatibility, either with wired Modbus or Modbus/TCP.@twistedtree - I may be following in your footsteps yet! I'm interested in how the Modbus stuff is going, otherwise I'll be heading more towards the DIY and home assistant for both control and monitoring if I ever throw Maretron (definitely not impossible!)

Because it's so reliable and well proven, I'm comfortable using PLCs, modbus, etc for controlling stuff on the boat, where I'm not comfortable using N2K for that. So my PLC/Modbus system monitors all my AC power sources (shore cords and generators), detects power and automatically connects the load panels (inverter, non-inverter, and HVAC loads), automatically controls the isolation transformer boost switch for dealing with 208 vs 240V shore power, and my new favorite - automatically adjusts the VIctron Inverter input load limit based on the capacity of the power source, and what other loads are connected. So the only manual operation is to plug/unplug shore cords, and start/stop generators, and the system does all the rest, assuming I have it in Auto mode. It can all be controlled manually too. And it even does generator autostart when the batteries drop below a set point. It's nice to know that I can leave the boat and if the shore power fails, the inverter will keep everything running. And if the batteries get low, the generator will recharge them. And when shore power is restored, everything will switch back. I know a lot of people don't like automation, but for me it comes down to on simple question. Is it reliable? Automation that works is awesome, and automation that doesn't work sucks. So far this all works.

Last edited by a moderator: