potoboat

Newbie

Hi all,

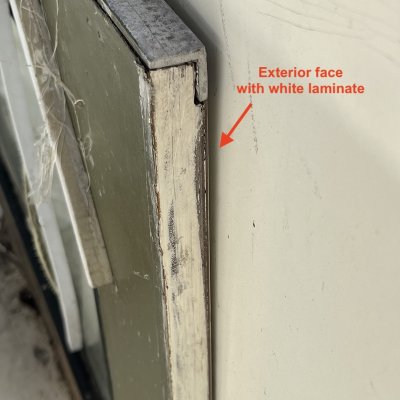

I'm looking at building a replacement helm door for my 73 Pearson Portsmouth. The existing door is rotted along the foot. The aluminum frames and hardware are actually in decent shape or can be easily refurbished, and the door itself is plywood, so it seems like a pretty straight-forward project. The previous door has a white laminate on the exterior side, thin and hard. I'm not sure if it's vinyl, gelcoat or something else, but I've also seen it used quite a bit in houseboat construction which makes me think it is (or was) a commonly available product. Does anyone know what it might be and how I could acquire some?

I'm looking at building a replacement helm door for my 73 Pearson Portsmouth. The existing door is rotted along the foot. The aluminum frames and hardware are actually in decent shape or can be easily refurbished, and the door itself is plywood, so it seems like a pretty straight-forward project. The previous door has a white laminate on the exterior side, thin and hard. I'm not sure if it's vinyl, gelcoat or something else, but I've also seen it used quite a bit in houseboat construction which makes me think it is (or was) a commonly available product. Does anyone know what it might be and how I could acquire some?