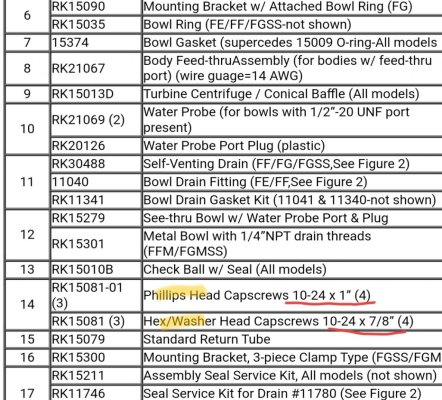

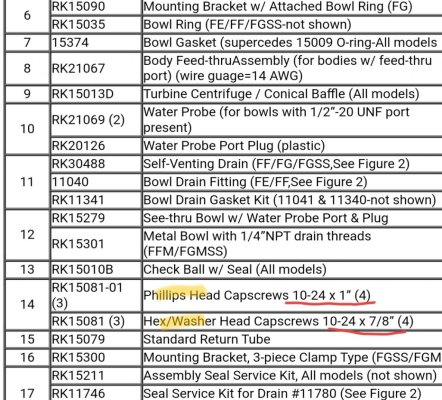

If indeed you have purchased 3 sets of RK15081, 12 hex washer head cap screws, why don't you use them?

If they don't thread in to the body, try this. Take a small piece of cloth, saturate it with vinegar and stuff it in the threaded fastener hole for about 15 minutes.

Remove the cloth and twist a brass (or stainless) 3/16" diameter bottle (or pipe cleaning) brush in the hole following the threads. Amazon has them, but buy a kit of various sizes if possible as you will need them later for other threaded holes. Size here is important as you want the ends of the bristles to clean out the threads. Don't use a 1/4" brush as you with crush it.

Rinse well using a trigger bottle with water (plus baking soda if you are anal) then twist in a pipe cleaner with a rag cover to dry the threads.

Now try you new Racor RK15081's by hand, they should go easily. If not, repeat the process.

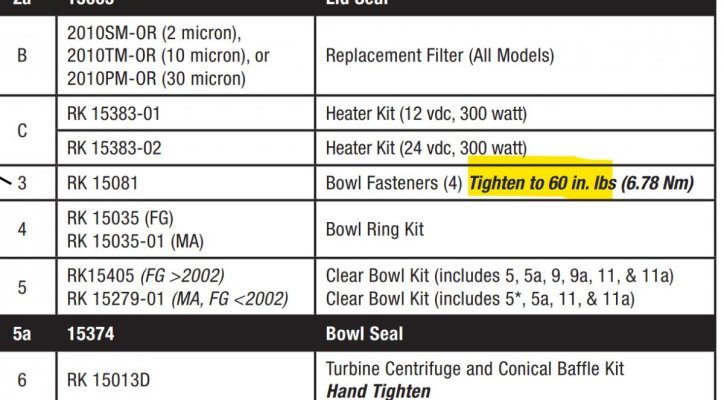

You stated that you intend to torque these machine screws to 60 inch pounds. Are you sure about that? A #10-24 stainless? machine screw can only be torqued to about 22 inch pounds Max, much more and you will likely twist the head off or pull the threads out of the aluminium body. Wouldn't that be a joy!

If the requirement is for 60 "/lbs. the machine screws and a threaded insert cast into the body would both need to comply with ASTM 574 which is a carbon steel, quenched and tempered fastener/insert, that in that size is exceedingly rare. I doubt Racor would use such a thing as by simply upsizing to a 1/4"-20 bolt, like on their larger units, would allow that amount of torque. All you are doing is compressing a square section O ring to affect a seal in a non-pressurized vessel, why so tight using such a small fastener?

If you try to cut a drive slot in the original damaged machine screws you could easily twist off half of the head leaving you hooped. The original Phillips drive was likely damaged by someone using the wrong tool, while trying to drive the fastener up hand. Don't repeat other peoples mistake.

Clean the threaded bores and use the new hex washer head fasteners.