jefndeb

Guru

Hello all-

I had my primary anchor chain (140' of 5/16) hot dip re-galvanized at a local galvanizing foundry, which I think was a mistake in the end...

When I called to ask the foreman about this he said he could do it but that to expect "a few" links might be stuck together. He said all I had to do was to tap a few of them with a rubber mallet to break them loose. He only quoted me $100 so I figured it to be a good idea....Wrong...

I had to spend about 4 hours beating each link with a large heavy hammer over a big piece of wood to break the links apart. And I still didn't do a good job because there are still links stuck together. I probably also broke loose half the zinc coating in doing so

I considered silly stuff like renting a cement mixer and rolling the chain around to work the links loose but I had to do something, I should have bought all new chain but I didn't realize the chain would look like it overdosed on viagra.

I also bought 2 cans of cold zinc spray, which is really just paint with some zinc in it, and tried to re-coat the chain.

Anyway, I do not recommend this to anyone unless the facility is setup to hot dip chain.

I worked it around our Lewmar Concept 1 windlass 3 or 4 times when we anchored this past weekend and it worked fine other than a few kinks and twists here and there, and there are tidbits of zinc chips everywhere in the windlass area and anchor locker.

I say all this because I was under the impression, based from the survey and my ignorance that I had 3/8" anchor chain, which seemed correct for my 40 foot trawler. I had also installed a Rocna 25kg anchor last summer and felt I had a reasonably good setup.

But today a dock neighbor today gave me 120' of fairly new Trident 3/8" BBB anchor chain. This chain he gave me looked surprisingly bigger than my chain which made me question the size of mine.

Turns out after doing some measuring that I have only 5/16" chain.

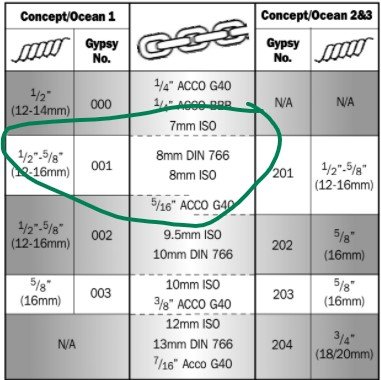

And it looks like my gypsy would have to be replaced to accept this new 3/8" chain.

Question I am asking after all this bla bla is -

Is there a ABYC recommendation chart to shows vessel length/weight to show proper anchor chain sizes per vessel size?

Thanks, sorry for the long story.

Jeff

I had my primary anchor chain (140' of 5/16) hot dip re-galvanized at a local galvanizing foundry, which I think was a mistake in the end...

When I called to ask the foreman about this he said he could do it but that to expect "a few" links might be stuck together. He said all I had to do was to tap a few of them with a rubber mallet to break them loose. He only quoted me $100 so I figured it to be a good idea....Wrong...

I had to spend about 4 hours beating each link with a large heavy hammer over a big piece of wood to break the links apart. And I still didn't do a good job because there are still links stuck together. I probably also broke loose half the zinc coating in doing so

I considered silly stuff like renting a cement mixer and rolling the chain around to work the links loose but I had to do something, I should have bought all new chain but I didn't realize the chain would look like it overdosed on viagra.

I also bought 2 cans of cold zinc spray, which is really just paint with some zinc in it, and tried to re-coat the chain.

Anyway, I do not recommend this to anyone unless the facility is setup to hot dip chain.

I worked it around our Lewmar Concept 1 windlass 3 or 4 times when we anchored this past weekend and it worked fine other than a few kinks and twists here and there, and there are tidbits of zinc chips everywhere in the windlass area and anchor locker.

I say all this because I was under the impression, based from the survey and my ignorance that I had 3/8" anchor chain, which seemed correct for my 40 foot trawler. I had also installed a Rocna 25kg anchor last summer and felt I had a reasonably good setup.

But today a dock neighbor today gave me 120' of fairly new Trident 3/8" BBB anchor chain. This chain he gave me looked surprisingly bigger than my chain which made me question the size of mine.

Turns out after doing some measuring that I have only 5/16" chain.

And it looks like my gypsy would have to be replaced to accept this new 3/8" chain.

Question I am asking after all this bla bla is -

Is there a ABYC recommendation chart to shows vessel length/weight to show proper anchor chain sizes per vessel size?

Thanks, sorry for the long story.

Jeff

Attachments

Last edited: