I consider myself an able bodied person. I have been caring for my Lehman 120 and never miss a service interval. When I got the boat, I redid the head gasket, injectors, injector lines, alternator upgrade, starter, raw water pump upgrade, Fresh water pump, antifreeze overflow system, all hoses, belts etc... All of it was “easy peasy”

The one thing I bought, but never did was the damper plate. It sat in a shelf for a few years, and I put 2000 hours in her. (Took my Groverbuilt 26 from Cape May to The Cape in Mass.)

I decided to do it this weekend. What a bitch. I now know why folks don’t change them. On the surface, easy job. Unbolt prop shaft, push back, unbolt tranny housing, support engine, pull tranny back a few inches, then “just swap out the plate”

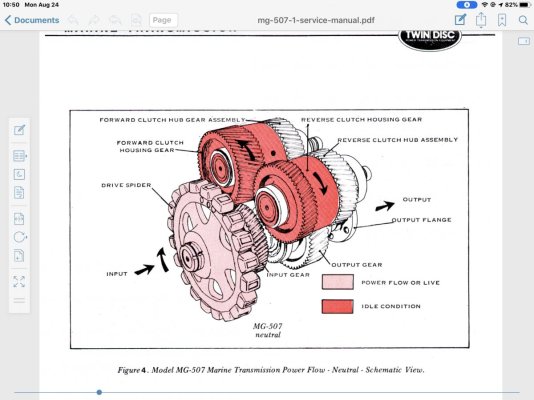

Well, my damper was frozen to the splines on the transmission. That meant nothing was coming apart. I’m a big guy and manhandling a BW 72 series tranny was like taking the dog for a walk.

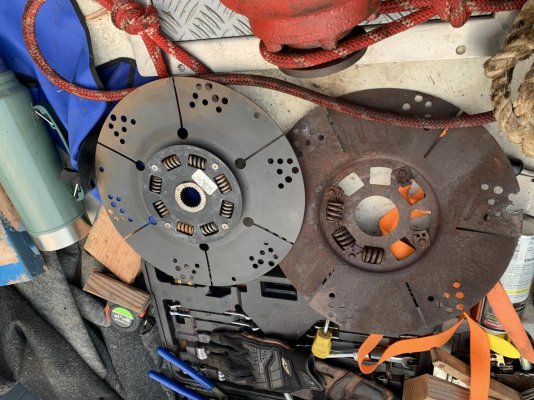

Until this. We must have tugged and sworn at the transmission for 3-4 hours. Finally, the damper plate splits in two (see pick) and the spring part stuck with the tranny, and the other half was still bolted to the fly wheel. All said and done, took me about 5-6 hours and Motrin.

Is there something I could have done to avoid this?