dwhatty

Moderator Emeritus

- Joined

- Sep 25, 2008

- Messages

- 2,846

- Location

- USA

- Vessel Name

- "Emily Anne"

- Vessel Make

- 2001 Island Gypsy 32 Europa (Hull #146)

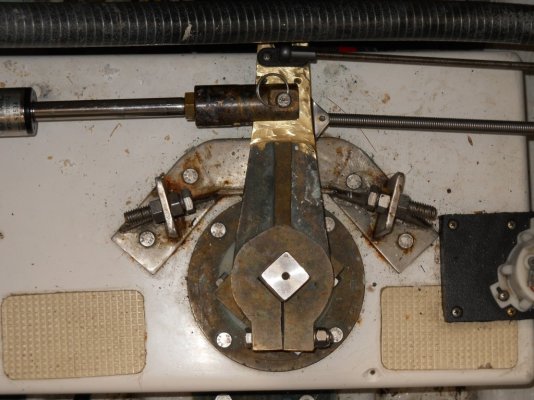

Steering from lock to lock on our boat (Coursemaster Hydrive hydraulic system) was almost 6 turns. Too much for me, especially in a following sea. The sole US Hydrive rep said to buy a new ram and helms (for two stations), which would have been very expensive. But when I said I couldn't afford that, he got very helpful and suggested, if my tiller arm setup and rudder stops would allow it, to move the pivot point where the ram connects to end of the tiller arm in from 8" from the center of the rudder shaft to 6" from it. He said steering effort might go up a bit.

So, with a little machining and moving of the attachment points of the rudder indicators, I did it.

Now I have 4 turns lock to lock and steering effort is barely noticeable. Before the change, there was zero effort which was a bit disconcerting to me

So, with a little machining and moving of the attachment points of the rudder indicators, I did it.

Now I have 4 turns lock to lock and steering effort is barely noticeable. Before the change, there was zero effort which was a bit disconcerting to me