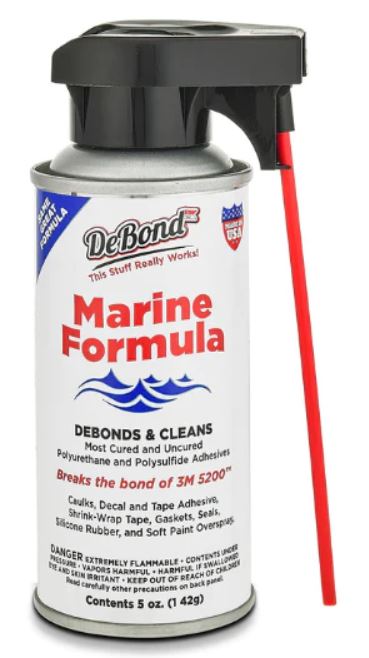

I had to take apart a piece off fiberglass/gel coat.

But a lot is still left behind.

the area is about a sq foot, I used a sharp wood chisel to get the bulk of it but don't want to damage the gel coat.

Was thinking about a heat gun but worried again about the get coat.

Any ideas

But a lot is still left behind.

the area is about a sq foot, I used a sharp wood chisel to get the bulk of it but don't want to damage the gel coat.

Was thinking about a heat gun but worried again about the get coat.

Any ideas