You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Windlass, not a clue!!!

- Thread starter Portuguese

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Nomad Willy

Guru

Looks like one or more of the mods actually wants us talking about anchoring. Perhaps they just want us talk'in.

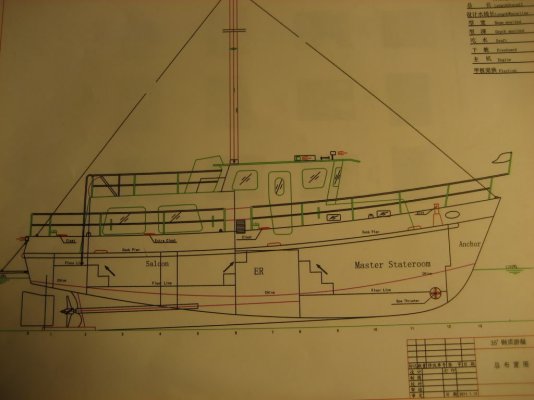

Jay, * Thanks for the Sea Ray story. Helps to show that weight effects performance very much and unnecessary weight is not good unless it's intended ballast. The only reason to use chain on a rode is for abrasion resistance and to affect enough catenary for good anchor performance. The weight of the chain helps keep the anchor shank low enough to allow the anchor to dig in and penetrate the bottom. The advantage of the weight decreases quickly the further away from the anchor one gets. and of course the anchor chain still in the anchor locker does no one any good at all. I don't much care for the low performance anchors the fishermen here in SE use but they do have the perfect rode. Super heavy chain, very heavy chain, heavy chain and the rest heavy nylon line. Some are all chain though but not the majority. Notice the two different sizes of chain on this old boat. Some have 3 sizes. One can only do that w a reel winch or pulling by hand. It does show, however that they are making an effort to get the weight at the business end of the rode. And the fact that most of them use nylon line on the boat end of the rode amplifies that principle.*

I'm going to change my opinion on the all chain issue somewhat. I based much of the above on a assumed fact that probably is'nt a fact. That is that when an all chain rode is in a bad blow it's chain is straight out and has lost all of it's catenary. I remember when I heard that that I thought it could'nt be true and thinking back I think I was right. I don't think any anchor can hold that well nor is it likely a boat could put that much tension on a rode. Also it seems to me the source of that so-called fact was that Smith guy from Rocna. Can't believe I bought that. Dos'nt change what I think the perfect rode should be though. Two or three sizes of chain (about 15 - 30') and nylon line.

-- Edited by nomadwilly on Tuesday 18th of October 2011 01:32:20 PM

Jay, * Thanks for the Sea Ray story. Helps to show that weight effects performance very much and unnecessary weight is not good unless it's intended ballast. The only reason to use chain on a rode is for abrasion resistance and to affect enough catenary for good anchor performance. The weight of the chain helps keep the anchor shank low enough to allow the anchor to dig in and penetrate the bottom. The advantage of the weight decreases quickly the further away from the anchor one gets. and of course the anchor chain still in the anchor locker does no one any good at all. I don't much care for the low performance anchors the fishermen here in SE use but they do have the perfect rode. Super heavy chain, very heavy chain, heavy chain and the rest heavy nylon line. Some are all chain though but not the majority. Notice the two different sizes of chain on this old boat. Some have 3 sizes. One can only do that w a reel winch or pulling by hand. It does show, however that they are making an effort to get the weight at the business end of the rode. And the fact that most of them use nylon line on the boat end of the rode amplifies that principle.*

I'm going to change my opinion on the all chain issue somewhat. I based much of the above on a assumed fact that probably is'nt a fact. That is that when an all chain rode is in a bad blow it's chain is straight out and has lost all of it's catenary. I remember when I heard that that I thought it could'nt be true and thinking back I think I was right. I don't think any anchor can hold that well nor is it likely a boat could put that much tension on a rode. Also it seems to me the source of that so-called fact was that Smith guy from Rocna. Can't believe I bought that. Dos'nt change what I think the perfect rode should be though. Two or three sizes of chain (about 15 - 30') and nylon line.

-- Edited by nomadwilly on Tuesday 18th of October 2011 01:32:20 PM

Attachments

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

*Don't think my windlass would like handling different sizes of chain at the same time.nomadwilly wrote:

. Two or three sizes of chain (about 15 - 30') and nylon line.

Attachments

Nomad Willy

Guru

So whad'ua married to your winch? Seriously that's the problem. Most everybody here has a gypsy to handle their chain. It only takes one size. But you've got 4 choices. You can go or stay all chain, splice line to chain and get a windlass that pulls and wraps both chain and line, get a winch that has a drum and gypsy and go out on deck to transfer from drum to gypsy when chain comes up or get a reel winch. The latter is what I'd do if I was just about any one of you. But if the chain locker storage was OK I could see a gypsy/drum winch. Seems to me I looked for one and could'nt find it. I like my "Brait" rode and don't know if it can be spliced to chain or not. If it really is dependable the splice seems to be the slickest route to a good rode but I don't like the splice. If I could be convinced of it's strength and learn how to make the splice perhaps I'd do it. I wonder if I could mount a winch above deck and pick up the rode as it comes aboard (underneath the winch) and put it in my anchor box. There are options but unless my present winch dies the set-up I have now is fine. Anchor, winch, rode and storage. But a lot of guys are tied to all chain because it dos'nt involve any more spending or learning.

OH Shrip, * *That old anchor is a "Dreadnaught" *...like the old battleships.

-- Edited by nomadwilly on Tuesday 18th of October 2011 06:15:52 PM

OH Shrip, * *That old anchor is a "Dreadnaught" *...like the old battleships.

-- Edited by nomadwilly on Tuesday 18th of October 2011 06:15:52 PM

That is indeed, a true fact.* In Earl Hinz's book "The Complete Book of Anchoring and Mooring" is a fairly dramatic*photograph of a Coast Guard cutter at anchor off a lee shore.* The photo was taken from a helicopter*during a rescue attempt in a storm and the cutter's*anchor chain is stretched absolutely bar tight.* It broke shortly after the photo was taken, and as I recall, this was the vessel's second attempt at anchoring after the same thing had happend in their first attempt with their other anchor and rode.* Hinz included this photo and the story that went with it as part of his explanation of the downside of an all-chain rode in severe conditions like this which will remove every bit of catenary and thus shock absorbing ability of the chain.nomadwilly wrote:

*I based much of the above on a assumed fact that probably is'nt a fact. That is that when an all chain rode is in a bad blow it's chain is straight out and has lost all of it's catenary.

So you were not at all incorrect in your assumption that all-chain can lose all its catenary and shock absorbing.* Eventually, if the conditions are bad enough, either the chain will break or the on-board hardware that's taking all the strain will.* However, it takes a fair amount of wind to do this.* How much wind will obviously depend on the windage of one's boat, the size of the waves, and so on.* So it's probably not a condition most of us recreational boaters*are ever likely to face in the protected coastal waters of the PNW, BC, and SE Alaska with the good weather forecast coverage we have.* But I imagine strong winds and big waves can be a regular occurance the exposed anchorages of places like the Southwestern Pacific.

Bendit

Senior Member

- Joined

- Nov 25, 2007

- Messages

- 326

- Location

- New Zealand

- Vessel Name

- Pioneer

- Vessel Make

- Westcoaster 53 converted to pleasure

Have certainly experienced our all-chain rode dead straight and bar tight. When this happens, I realise I probably should have chosen a better anchorage. If the scope is sufficient (10 or more to 1), the anchor will still hang*in as I have never dragged in these situations, but it certainly keeps the pucker factor up, especially in a crowded anchorage when everyone's out on deck and worried.*It's always worse at night when you can't see what the other boats are doing. We use a Y-shaped nylon snubber going to both foredeck cleats.

You try not to get into these situations, but it still seems to happen every couple of years or so...

A*crowded anchorage is a good reason*to use an*all chain rode as it reduces the swinging room required.

You try not to get into these situations, but it still seems to happen every couple of years or so...

A*crowded anchorage is a good reason*to use an*all chain rode as it reduces the swinging room required.

Nomad Willy

Guru

Jeff,

In a crowded anchorage the chain rode has an obvious advantage until the wind starts blowing seriously and numerous boats start overlapping w different scopes. When all the ground tackle is maxed out it will probably be the boat w the longest scope that is the last boat to be blown up on the beach. But almost never does the maxed out situation come to pass (as Marin points out) and reduced swinging room in lesser conditions is indeed a plus. Perhaps I should quit knock'in it and switch even though it's not best theoretical system for a boat in a large and excellent anchorage that seldom exists. Perhaps I'm too much an idealist and not enough of a realist. I could store my present XYZ anchor on deck and put the chain below after washing much more like the typical trawler skipper does. I'll have to think about that. Thanks for responding re the straight chain rode. That changes the equation to some degree.*

In a crowded anchorage the chain rode has an obvious advantage until the wind starts blowing seriously and numerous boats start overlapping w different scopes. When all the ground tackle is maxed out it will probably be the boat w the longest scope that is the last boat to be blown up on the beach. But almost never does the maxed out situation come to pass (as Marin points out) and reduced swinging room in lesser conditions is indeed a plus. Perhaps I should quit knock'in it and switch even though it's not best theoretical system for a boat in a large and excellent anchorage that seldom exists. Perhaps I'm too much an idealist and not enough of a realist. I could store my present XYZ anchor on deck and put the chain below after washing much more like the typical trawler skipper does. I'll have to think about that. Thanks for responding re the straight chain rode. That changes the equation to some degree.*

Eric--- The point you have made continuously about your boat's sensitivity to weight in the bow is as valid now as it was when you first said it.* A combination rode can work very, very well as evidenced by the bazillion boaters who use them.*

As you well know, among its advantages are built-in shock absorbing and low weight compared to all-chain.* I think all -chain is the best way to go for boats that can accomodate it without compromising trim.* But this does not mean I think that boats that will do better with a combination rode should use all-chain instead.* They should use an anchor sized for effectiveness with a combination rode as well as sufficient chain to help the anchor set and keep the angle of pull as low as is practical.

But don't change just because some guys whose boats can accomodate all-chain make a good case for using it.* What's right for those boats is not automatically right for yours.* I've defended our use of all-chain a bunch of times on this forum, but I don't believe I've ever suggested that you should change to it on Nomad Willy.

-- Edited by Marin on Tuesday 18th of October 2011 10:39:24 PM

As you well know, among its advantages are built-in shock absorbing and low weight compared to all-chain.* I think all -chain is the best way to go for boats that can accomodate it without compromising trim.* But this does not mean I think that boats that will do better with a combination rode should use all-chain instead.* They should use an anchor sized for effectiveness with a combination rode as well as sufficient chain to help the anchor set and keep the angle of pull as low as is practical.

But don't change just because some guys whose boats can accomodate all-chain make a good case for using it.* What's right for those boats is not automatically right for yours.* I've defended our use of all-chain a bunch of times on this forum, but I don't believe I've ever suggested that you should change to it on Nomad Willy.

-- Edited by Marin on Tuesday 18th of October 2011 10:39:24 PM

Portuguese

Guru

Eric

I think that you've said it all. What works for you may not work for me, Each boat is a different case and I think that a boat in the 40's LOA sufferes a lot with 1000 lbs of weight in the bow!

Portuguese

I think that you've said it all. What works for you may not work for me, Each boat is a different case and I think that a boat in the 40's LOA sufferes a lot with 1000 lbs of weight in the bow!

Portuguese

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Heard it's good to keep weight off the boats' ends, but*you'd think a good boat designer would provide for the weight of adequate anchor(s) and chain.

Nomad Willy

Guru

Port, * Thanks but I don't completly agree. That's what Marin's trying to do * ....flush the debate down without admitting any wrong thinking or doing. My boat (and of course others like it) is right at the edge where it's starting to get difficult to handle anchoring by hand. It was so convenient w my last boat (25' Albin that was 1/4 the disp of my present Willard) that I'm having difficulty discarding the theory that w a bit of an edge (like a super performance anchor) I should be able to anchor by hand fairly easily and safely. At one time we could. In 1940 I could discard my CQR or Navy anchor, switch to a Danforth and cut the weight of my ground tackle to less than half of previous. That kind of performance advantage would get me to where I wanted to be when I bought the Willard. I thought I found the edge w the XYZ anchor. The original was 13lbs and short compared to the latest. It won 1st place in one anchor test (in mud) beating all other anchors soundly. Most skippers w the Willard 30 have all chain and a winch but we did'nt have the time to install same when we did the refit 4 years ago in Puget Sound. So I bought the XYZ to try out on the way home. Willy had gone over 30 years w a 15lb Danforth and 10' of 5/16" chain. 30' Willard's were not sold w a winch. All went well except I was having trouble getting the XYZ to set so I used the old Danforth*a lot of the time. When we got to Allison Harbor (so of Cape Caution) winds of over 50 knots were forecast for the next day. Wanting the extra holding power of the XYZ I managed to get it to set well and we hung on it w 50 knot winds w higher gusts for about 30 hrs. Anchor did'nt move. Somehow I don't think the Danforth would have held but it may have. But the XYZ did so I was keen to learn how to use it. But Allison Hbr was mud and over the next year it was obvious the XYZ was'nt going to cut it on other bottoms. Rarely could I get it to set. Then I noticed XYZ came out w a new anchor that was similar but considerably different. I decided it was a winch and some regular anchor or get lucky w the new anchor so I took a chance on the new XYZ. It's 18lbs. About the limit for handling by hand w a short chain. Iv'e used it about 10 times now (didn't boat much this year) and it's worked perfectly every time but we've not even experienced 30 knot winds this year and I have anchored w the old Danforth in 35 knot winds. I bought the new XYZ from Dragomir (the designer*and manufacturer) in NY. Not cheap at $450. To give the new anchor my best shot I bought a small electric winch and doubled the amount of chain. So far so good but I've really only tested the XYZ's ability to properly set and it has (unlike the original). Drago*wanted me to find a big fish boat, set the anchor and try to pull it out w 300hp and a huge prop. I think that's a lot to ask of a skipper and I have'nt. Anyway that's where I am at present and I may not change anything and furthermore I may have almost have achieved my objective.*

So Portuguese, I think you are right and wrong. Happily I can say mostly right. Extra weight is always bad but sometimes we can take some extra weight (hopefully small amount) to achieve a larger amount of good like greatly enhanced simplicity or convenience. The latter is where most trawler owners are w their chain and Bruce anchors. The Bruce gained popularity and remains popular mostly because it fits on the bow so well and looks indestructible. And most trawler skippers think weight is virtuous so a Bruce and lots or all chain is very popular. But I do think a special purpose system for special people and places is very valid but not very often encountered. I think a good anchor rode should work well on most all boats most anywhere in the world. There are slight exceptions like a Super Max may be better than anything in Florida if all they have is sand. But most all of us need a system that is very general in nature, not being specialized in any way. Many to most trawler systems are not high performance systems because they need that flexibility more than ultimate performance. I need the high performance because of the size of my boat so I don't need to double the weight of my ground tackle. Most of the reason for that is the size and disp of my boat. If I had a 36' boat much of my system would be different so Port is right that different strokes for different folks does apply but I think it applies to perhaps to less than 20% of us.*

So Portuguese, I think you are right and wrong. Happily I can say mostly right. Extra weight is always bad but sometimes we can take some extra weight (hopefully small amount) to achieve a larger amount of good like greatly enhanced simplicity or convenience. The latter is where most trawler owners are w their chain and Bruce anchors. The Bruce gained popularity and remains popular mostly because it fits on the bow so well and looks indestructible. And most trawler skippers think weight is virtuous so a Bruce and lots or all chain is very popular. But I do think a special purpose system for special people and places is very valid but not very often encountered. I think a good anchor rode should work well on most all boats most anywhere in the world. There are slight exceptions like a Super Max may be better than anything in Florida if all they have is sand. But most all of us need a system that is very general in nature, not being specialized in any way. Many to most trawler systems are not high performance systems because they need that flexibility more than ultimate performance. I need the high performance because of the size of my boat so I don't need to double the weight of my ground tackle. Most of the reason for that is the size and disp of my boat. If I had a 36' boat much of my system would be different so Port is right that different strokes for different folks does apply but I think it applies to perhaps to less than 20% of us.*

Nomad Willy

Guru

Mark,

That's a very very good point and w far reaching design and operational blessings. A typical canoe suffers terribly from all the weight (load) in the far ends. Boats and airplanes are FAR better off w their loads centered. Sterns and tails move quickly and easily to change direction and boats w a light bow will rise up to a wave and be very resistant to plunging in. The best balanced boats have most of the heavy stuff centered in the hull. One of the wonderful things about a straight inboard boat is that the engine is right where it belongs ...in the middle of the boat. Fuel, batteries, gen sets, water tanks and other heavy stuff is best placed there too but there is only so much room in the engine compartment so frequently one finds water tanks aft. Very good point Mark and often not considered after the designer has done his work.*

That's a very very good point and w far reaching design and operational blessings. A typical canoe suffers terribly from all the weight (load) in the far ends. Boats and airplanes are FAR better off w their loads centered. Sterns and tails move quickly and easily to change direction and boats w a light bow will rise up to a wave and be very resistant to plunging in. The best balanced boats have most of the heavy stuff centered in the hull. One of the wonderful things about a straight inboard boat is that the engine is right where it belongs ...in the middle of the boat. Fuel, batteries, gen sets, water tanks and other heavy stuff is best placed there too but there is only so much room in the engine compartment so frequently one finds water tanks aft. Very good point Mark and often not considered after the designer has done his work.*

RickB

Scraping Paint

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

Well, not that good a point.

Just read the threads on anchoring and anchor rodes. All line, all chain, big heavy anchors, little light anchors ... the weight of the ground tackle is all over the board. A design that provides for the heaviest weight imaginable hanging off the pulpit or concentrated in a chain locker is going to have hydrostatic curves that make it miserable for most other purposes.

You want a bow that rises rapidly with every wave? Then you get one that will probably make everyone onboard sicker than a dog in the slightest chop and will knock your teeth out by heaving and slamming in certain wave periods. And if that same boat is used by a guy who believes in a lunch hook tied to clothesline, he probably* won't be able to see anything but sky out the wheelhouse windows.

The design is all a compromise, put all the weight in the middle and the boat pitches like mad, slams, and is very sensitive to trim and will probably scare you to death in a following sea. Put it at the ends and you have to* provide for a fuller body to support the weight or accept some exciting moments with boarding seas and have to pay for more power to move it.

All boats are a compromise.

Just read the threads on anchoring and anchor rodes. All line, all chain, big heavy anchors, little light anchors ... the weight of the ground tackle is all over the board. A design that provides for the heaviest weight imaginable hanging off the pulpit or concentrated in a chain locker is going to have hydrostatic curves that make it miserable for most other purposes.

You want a bow that rises rapidly with every wave? Then you get one that will probably make everyone onboard sicker than a dog in the slightest chop and will knock your teeth out by heaving and slamming in certain wave periods. And if that same boat is used by a guy who believes in a lunch hook tied to clothesline, he probably* won't be able to see anything but sky out the wheelhouse windows.

The design is all a compromise, put all the weight in the middle and the boat pitches like mad, slams, and is very sensitive to trim and will probably scare you to death in a following sea. Put it at the ends and you have to* provide for a fuller body to support the weight or accept some exciting moments with boarding seas and have to pay for more power to move it.

All boats are a compromise.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

*The Coot, and probably most similar boats, have their engine(s), batteries, and genset (if I had one) located*near the center of the boats.* My Coot has*four fuel tanks totaling 318 gallons are immediately astern, and astern of that are two water tanks totaling about 200 gallons.* With tanks full, the stern drops about 2-3 inches and the boat levels out when tanks are*well below half.* Weight of those fluids is over a ton-and-a-half, no?* Anyway, I don't plan on filling to maximum capacity anyway unless intending a very*long non-stop cruise.nomadwilly wrote:

*One of the wonderful things about a straight inboard boat is that the engine is right where it belongs ...in the middle of the boat. Fuel, batteries, gen sets, water tanks and other heavy stuff is best placed there too but there is only so much room in the engine compartment so frequently one finds water tanks aft.

Attachments

RickB

Scraping Paint

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

*markpierce wrote:The Coot, and probably most similar boats, have their engine(s), batteries, and genset (if I had one) located*near the center of the boats.*

That's because the only useable volume in a short boat with a hull that isn't proportioned like a barge is in the centerbody.

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,180

"All boats are a compromise."

Agreed!!!

Agreed!!!

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

*And with a straight shaft and an engine not wanting to lean more than 12 degrees, the engine got to be located well-away from the stern.RickB wrote:

That's because the only useable volume in a short boat with a hull that isn't proportioned like a barge is in the centerbody.

Attachments

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

As much as I like the (under-rated and innovative) P-39 Airacobra, I'm not sure I'd like the additional gears/complication of jack shafts.

skipperdude

Guru

No idea what a Jack shaft is unless it is an anatomical refrence.

SD

SD

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

A jackshaft, also called a countershaft, is a common mechanical design component used to transfer or synchronize rotational force in a machine. A jackshaft is often just a short stub with supporting bearings on the ends and two pulleys, gears, or cranks attached to it.

skipperdude

Guru

Wow!! More information than I needed. But now I know.

Thanks mark.

SD

Thanks mark.

SD

RickB

Scraping Paint

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

*The use of cardan shaft drives has become a common solution for a lot of engine placement and drive "problems." They offer a lot of versatility and provide for soft mounting of engines to reduce vibration and noise as well as providing relatively simple alignment.Willy wrote:

I have seen the use of jack shaft systems on some of Bill Gardens boats. There is one of them vessels here for sale.

Tractor tugs (Z-drives) use them and more large yachts use them to allow better use of the mid body space that would otherwise be filled with machinery. Some of them are based on carbon fiber shafts and save a lot of weight in addition to their other benefits.

There are no additional gears associated with a cardan shaft drive, all it does is allow the gearbox to be mounted someplace away from the engine. A ten or twenty foot section of carbon fiber tube is far less weight than an equal length of propeller shaft, it absorbs torsional vibrations and it doesn't have transmit the same torque.

In the P-39 all it did was separate the reduction gear from the engine, there were no additional gears or complications. It was done that way because it allowed the engine to fill the fat part of the fuselage and provided room for the gearbox and cannon while reducing form drag.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

*The drive shaft of the P-39's engine (located behind the cockpit) was connected to a lower shaft running below the cockpit which in turn connected to a higher shaft connected to the propeller.** Gears were used to transfer power among the shafts.* *The engine's location*made room in the nose for heavy armanent (heavy machine guns and cannon) and provided for*a tricycle landing gear,*and made the plane highly maneuverable, but the rear engine required the pilot to work harder because the plane wasn't very stable, and the engine was exposed to enemy fire from the rear.RickB wrote:

In the P-39 all it did was separate the reduction gear from the engine, there were no additional gears or complications. It was done that way because it allowed the engine to fill the fat part of the fuselage and provided room for the gearbox and cannon while reducing form drag.

I've been in a P-39 a number of years ago that was being restored at the Planes of Fame Museum in Chino, CA. The driveshaft of the P-39 came straight out of the engine, ran forward under the pilot's seat to the nose where the power was stepped up via a simple gearbox to the short, hollow driveshaft of the propeller. There was no step-down gear train from the engine to the driveshaft The driveshaft from the engine to the propeller gearbox was in two sections with a coupler midway along to allow the driveline to accomdate the flexing of the fuselage.

The Oldsmobile T9 37mm cannon and two .50 machine guns occupied the entire nose of the plane. The cannon barrel projected through the hollow propeller driveshaft and hub. If additional machine guns were needed, they were mounted in pods carried underneath the plane's very thin wings.

The P-39 suffered from the lack of a good engine at altitude. The supercharger on the Allison V-12 was not all that great so the perormance of the plane fell off greatly with altitude. On the other hand, the driveshaft from the engine forced a higher placement of the pilot which gave him terrific visibilty. The Russians used the P-39 with great success as a ground attack plane.

The P-39 was so pitch and CG sensitive due to the engine placement that the 37mm cannon could not eject its shells overboard as it fired--- this would gradually shift the CG too far aft.* So the shell casings were retained in the magazine after firing. One of Bell's test pilots during the war was Tex Johnson, the man who famously rolled the Boeing Dash-80 over Seafair in Seattle.* I got to know Tex quite well in the early 1990s as I was contemplating writing a book in which a P-39 would play a major role and he agreed to tell me anything I wanted to know about the plane.* Tex told me a lot of great stories about the P-39 and flying it, including the fact that if you wanted to go fly one without live ammunition in the cannon magazine you had to load special dummy rounds that weighed the same as live ones.* If you didn't, the plane could kill you because the CG would be so much out of limits aft.

The Germans did something somewhat similar with their Bf-109. The design specification called for a cannon to carried in the nose firing through the propeller hub. In order to accomodate this, Daimler-Benz developed an inverted V-12 engine which mounted low in the nose. This is why the exhausts come out near the bottom of the cowl. A simple gearbox on the front of the engine carried the engine crankshaft rotation up to the hollow propeller shaft and hub, similar to what was done in the P-39. The cannon "lay" on top of the flat bottom of the engine and occupied the upper portion of the nose. The cannon barrel, like the P-39's, extended out through the hollow prop shaft and hub.

-- Edited by Marin on Wednesday 19th of October 2011 07:08:02 PM

The Oldsmobile T9 37mm cannon and two .50 machine guns occupied the entire nose of the plane. The cannon barrel projected through the hollow propeller driveshaft and hub. If additional machine guns were needed, they were mounted in pods carried underneath the plane's very thin wings.

The P-39 suffered from the lack of a good engine at altitude. The supercharger on the Allison V-12 was not all that great so the perormance of the plane fell off greatly with altitude. On the other hand, the driveshaft from the engine forced a higher placement of the pilot which gave him terrific visibilty. The Russians used the P-39 with great success as a ground attack plane.

The P-39 was so pitch and CG sensitive due to the engine placement that the 37mm cannon could not eject its shells overboard as it fired--- this would gradually shift the CG too far aft.* So the shell casings were retained in the magazine after firing. One of Bell's test pilots during the war was Tex Johnson, the man who famously rolled the Boeing Dash-80 over Seafair in Seattle.* I got to know Tex quite well in the early 1990s as I was contemplating writing a book in which a P-39 would play a major role and he agreed to tell me anything I wanted to know about the plane.* Tex told me a lot of great stories about the P-39 and flying it, including the fact that if you wanted to go fly one without live ammunition in the cannon magazine you had to load special dummy rounds that weighed the same as live ones.* If you didn't, the plane could kill you because the CG would be so much out of limits aft.

The Germans did something somewhat similar with their Bf-109. The design specification called for a cannon to carried in the nose firing through the propeller hub. In order to accomodate this, Daimler-Benz developed an inverted V-12 engine which mounted low in the nose. This is why the exhausts come out near the bottom of the cowl. A simple gearbox on the front of the engine carried the engine crankshaft rotation up to the hollow propeller shaft and hub, similar to what was done in the P-39. The cannon "lay" on top of the flat bottom of the engine and occupied the upper portion of the nose. The cannon barrel, like the P-39's, extended out through the hollow prop shaft and hub.

-- Edited by Marin on Wednesday 19th of October 2011 07:08:02 PM

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

You're right, Marin, there were only two shafts.

"... The solution adopted was to mount the cannon in the forward fuselage and the engine in the center fuselage, directly behind the pilot's seat. The tractor propeller was driven via a 10-foot-long (3.0 m) drive shaft which was made in two sections, incorporating a self-aligning bearing to accommodate fuselage deflection during violent maneuvers. This shaft ran through a tunnel in the cockpit floor and was connected to a gearbox in the nose of the fuselage which, in turn, drove the three- or (later) four-bladed propeller via a short central shaft. The gearbox was provided with its own lubrication system, separate from the engine; in later versions of the Airacobra the gearbox was provided with some armor protection. ..."

"... The solution adopted was to mount the cannon in the forward fuselage and the engine in the center fuselage, directly behind the pilot's seat. The tractor propeller was driven via a 10-foot-long (3.0 m) drive shaft which was made in two sections, incorporating a self-aligning bearing to accommodate fuselage deflection during violent maneuvers. This shaft ran through a tunnel in the cockpit floor and was connected to a gearbox in the nose of the fuselage which, in turn, drove the three- or (later) four-bladed propeller via a short central shaft. The gearbox was provided with its own lubrication system, separate from the engine; in later versions of the Airacobra the gearbox was provided with some armor protection. ..."

- Joined

- Apr 15, 2008

- Messages

- 13,738

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Eric, I have the 8-plait brait spliced to my anchor chain. It flows through my lesser windlass (Lewmar) with ease. I ordered mine already spliced to the chain from Defender.

Here's a link showing how to splice it.

Here's a link showing how to splice it.

RickB

Scraping Paint

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

"In the P-39 all it did was separate the reduction gear from the engine, there were no additional gears or complications."

What part of that is so difficult to understand? Instead of mounting the red gear to the engine it was mounted separately and connected by an extended shaft. There were no additional gears. Allison (now RR) used the same technique on the T-56 turboprop used on the P-3 and on C-130s with a shorter shaft to connect the engine to the gearbox.

"the rear engine required the pilot to work harder because the plane wasn't very stable"

Stability and maneuverability are two opposing values. The latest in fighter designs are impossible for a human to fly without a computer interface because they are so unstable ... and that is what makes them so incredibly effective. Boeing likes stability (to a point) but General Dynamics and Sukhoi happily trade that for maneuverability.

What part of that is so difficult to understand? Instead of mounting the red gear to the engine it was mounted separately and connected by an extended shaft. There were no additional gears. Allison (now RR) used the same technique on the T-56 turboprop used on the P-3 and on C-130s with a shorter shaft to connect the engine to the gearbox.

"the rear engine required the pilot to work harder because the plane wasn't very stable"

Stability and maneuverability are two opposing values. The latest in fighter designs are impossible for a human to fly without a computer interface because they are so unstable ... and that is what makes them so incredibly effective. Boeing likes stability (to a point) but General Dynamics and Sukhoi happily trade that for maneuverability.

Attachments

RickB

Scraping Paint

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

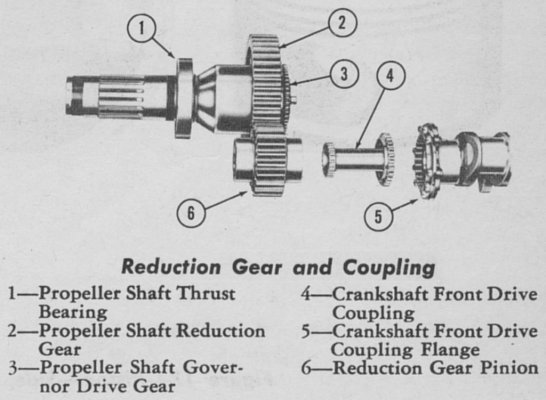

It seems that you need a drawing or a picture. P-39 did not use an additional shaft or gearing. The 10 foot long shaft simply replaced Item #4 in the drawing. It allowed the designer to separate the engine and the reduction gear.markpierce wrote:

You're right, Marin, there were only two shafts.

There were no extra shafts or gears used. The propeller shaft that you see is the same one that is used in the close coupled versions.

Attachments

I used the wrong term in describing the propeller end of the P-39's drive train. I said "short, hollow propeller driveshaft" or something like that. But as Rick's illustration shows there isn't a "driveshaft" turning the prop, it's attached to the output shaft of the reduction gearbox. I had the right layout, but used the wrong term.

Similar threads

- Locked

- Replies

- 9

- Views

- 4K

- Locked

- Replies

- 1

- Views

- 1K

- Locked

- Replies

- 17

- Views

- 8K