Unclematt

Senior Member

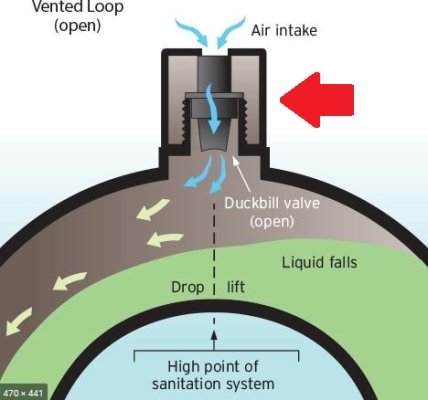

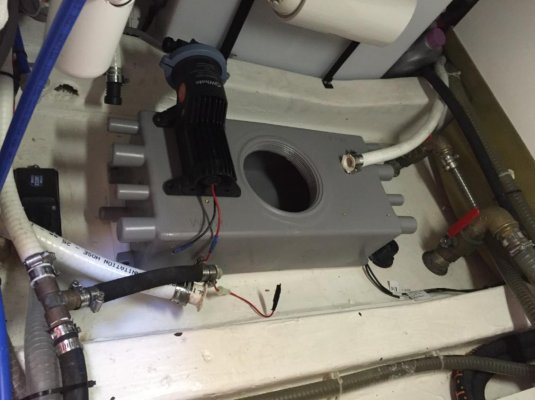

I have only has my boat 6 weeks and I know it needs some love. One repair at a time. My shower sump pump was blowing out the sides of the pump nothing was going out the sea cock. I thought clogged hose so I have replace the hose and checked to make sure the sea cock was clear. I replaced the pump with the same 800 gph pump on a float switch. Today I still have the same problem. So here is the question tonight I found that the vent loop vent was clogged so I have removed and cleaned it. Would that cause this issue? I wont be able to reinstall it until later this week. Thanks TF gurus