paulga

Guru

- Joined

- May 28, 2018

- Messages

- 1,026

- Location

- United States

- Vessel Name

- DD

- Vessel Make

- Marine Trader Sundeck 40'

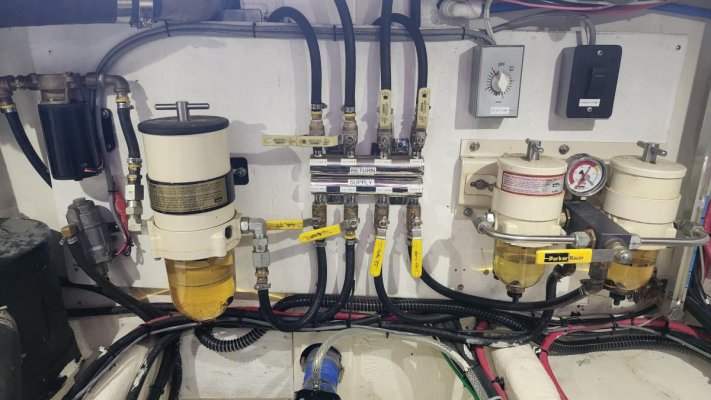

Actually, the instructions below say to turn the two 3way valves to the left to shut off the fuel. The yellow handles is labeled a bleed valve.

Right. This seems to be spelled out in the labels on the panel. If only all boats were so clearly set up. To summarize what it says:

- The Yellow handle valve is a bypass valve for use when you want to run the small aux pump to bleed the fuel systems.

- The three way valves below control the draw and return to/from the filters, with positions shown in the diagram. Right now it's set to use the #1 filter. Turn them to the Off position to change filters.

You have a really nicely set up and well documented/labeled fuel system.

Thanks guys for your inputs.

The three way valve should also shut off fuel to the generator racor, right? the bleeding pump should also cover the generator racor.

I have highlighted a section of short fuel hose from the gen racor to the tank (starboard). what's the fuel flow direction in that hose?

View attachment 143568

(the oil pads were from last filter change)

I think you are in the best position to answer these questions. We are all looking at the same things you are, but limited to the pictures you have posted. There are other people here with MT boats, but you need to keep in mind that every single boat is different. Many are different from the factory, and after 20+ years of ownership 100% of them have become different.

Trace your fuel lines, and you can answer these questions yourself, and probably with more accuracy than all of us looking at pictures. On your first question, just following the fuel lines and looking at the operating instructions gives you all the answers. It was actually remarkably well documented in the posted instructions. On your generator, look at where the filter hoses go. Look to see if there are IN and OUT indications on the filter housings as a way to confirm fuel flow. Will the filter be on the fuel flow that feeds the generator, or will it be on the fuel return to the tank? Look at how the bypass/primer pump is plumbed in. Does it bypass the generator filter? Does it push fuel through the generator to prime it, or does it only push fuel through the main engine(s)?

It's not that we don't want to help, but I think it's essential that you get practice and build confidence in figuring out some of this stuff yourself.

There should be shut offs at the tanks, if you are not sure DO NOT ATTEMPT THIS yourselfI'm planning to change racor filters and spin on filters later this week. I recall the first step is to shut off fuel. Is the yellow valve shown below the one? Turn it clockwise 90d shuts off the fuel? Are there any other valves to turn before ready to change the filters?View attachment 143531

If you pour fuel into the filter chamber and it comes out the drain on the bottom of the bowl, then the drain isn't closed. Is that what you are saying is happening?

I have never encountered a racor drain that closes counterclockwise. Always clockwise per normal thread rotation. BTW, the whole clockwise, counterclockwise things is always relative to facing the screw or device. So in the case of your filters, it's facing the bottom of the bowl.

I think you would benefit from some introductory books on plumbing, home maintenance, basic electrics, etc. Read them all cover to cover. Nigel Calder has a bunch of books, along with other people. I applaud your willingness to take this on and to learn, but you really are starting at ground zero.

If it’s draining out the bottom you don’t have the drain closed, or, There’s something going on with at drain, and you just need to figure it out. Try screwing it fully the other direction and see if it closes. If not, you may have a bad o-ring on it.

are you saying the draining fitting has an o-ring?

i saw this small o-ring came out together with the lid and gauge. It's smaller than the gauge bolt dia and looked worn out. I couldn't figure out where it was from.

i didn't see the same small o-ring when i replaced the engine racor fitlers.

View attachment 144039

when you loosen the drain fitting, the valve moves downwards, tightening moves it upward. correct?

There is and it needs to be changed along with the main gasket comes with the kitIf memory serves me correct, there is supposed to be an O-ring (as you show on the wire) under the Racor top lid. This seals the lid around the threaded stud that tightens the lid.

Every time you perform a filter change, you should replace the small O ring and the flat gasket around the outside of the lid. They are supplied with a new pleated filter. I keep the old O rings and gaskets just in case. Go on the Racor site to see how the fuel flow is, it may answer some of your questions. The bowl does not need to be completely full of diesel to work properly.

If memory serves me correct, there is supposed to be an O-ring (as you show on the wire) under the Racor top lid. This seals the lid around the threaded stud that tightens the lid.

Every time you perform a filter change, you should replace the small O ring and the flat gasket around the outside of the lid. They are supplied with a new pleated filter. I keep the old O rings and gaskets just in case. Go on the Racor site to see how the fuel flow is, it may answer some of your questions. The bowl does not need to be completely full of diesel to work properly.