With respect to wire supply, a google search reveals that a large chandlery (10 outlets) in Greece (as well as other smaller ones) stocks 10 Gauge Ancor tinned marine wire, just like they do in St. Peterburg FL.

Yeah I know, they all lie, all the time, just so that they can steal your money and see you in jail.

I have no full throated support for Victron and I have none of Victron's products. I've never even touched one, ever. My inverters/chargers are Outbacks, which are made in India and a legacy MSW Xantrex unit from 2003.

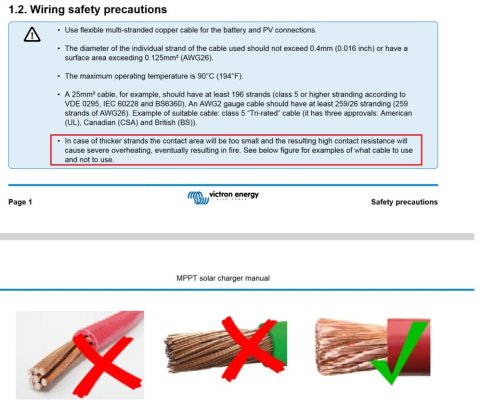

Mambo42's mistake likely was that a too large of wire was used, selected to try to reduce the voltage drop in the wire runs.

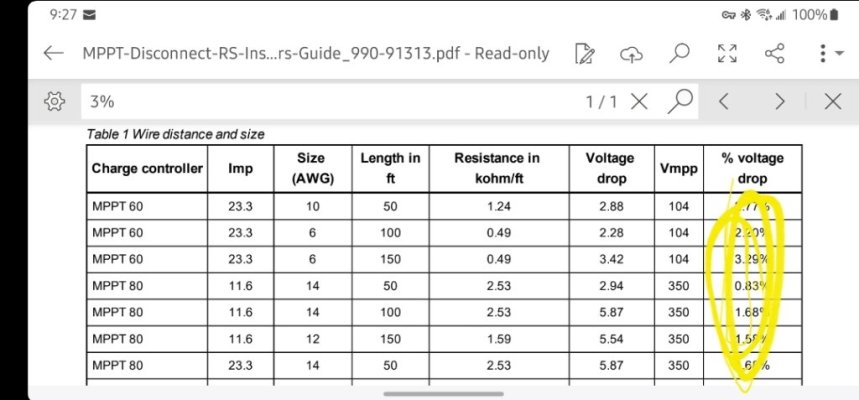

ABYC mandates a 3% limit for critical things like bilge pumps, Nav. equipment and running lights while 10% is Ok for the non critical stuff like interior lights, stereos, inverts etc. These are all consumers. While a 10% voltage drop may cause your lights to run a little dimmer, or you inverter to draw a bit more current to produce equivalent power, it's not harmful.

The same not harmful statement is true on the production side of the equation. Yes, voltage drop results in lost power due to the heat from resistance, but how often are you running your solar that close to flat out that it makes a difference when compared to upsizing the wire and burning up equipment or down the boat? Your battery may take 10% longer to get fully charged, but who cares, the charging current is produced with no ongoing cost.

ksanders said it before at 20 Amps and below use 12 gauge.

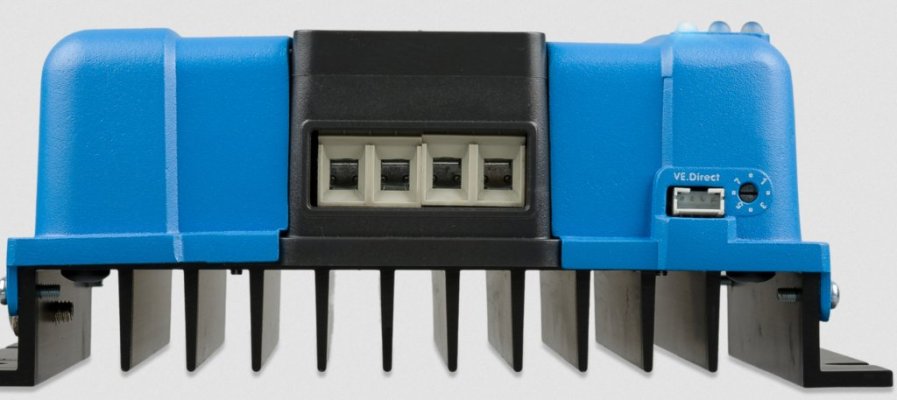

Victron's terminal block will accept 10 gauge c/w a ferrule, if according to CMS, you use the right crimper.

Victron says the terminal will accept 6 mm2 wire. (10 gauge is 5.26 mm2).

Why do we need to build a better mousetrap for 20 Amps?

Just to make it 100 % clear: I did not select anything. I bought the required equipment, handed it over to the electricians, told them what I wanted and they made it happen. They ripped out the old wiring, installed the new wiring, a welder made the frame for the solar panels and those were connected by the electricians.

It was Victron that prescribed a minimum of 5 mm2 cable to connect the solar panel to this MPPT controller, nobody else's idea. The electricians informed me that the cable (5 mm2, fire retardant) was not available and could not be ordered unless I ordered 50 mtr of red and 50 mtr of black for a price of 8 euro per meter. Little did I know that 5 mm2 was based on the American market, which we don't serve in the EU. In the EU we have EU standards.

50 mtr of red and 50 mtr of black would get to 800 euro for just a bit of cable, so I asked for a solution. That solution was either 4 mm2 or 6 mm2. According to the book, written by the founder of Victron, 4 mm2 is not enough to handle 15 A, so that became 6 mm2. At that time I did not know that the diameter of the hole in the connection block is only 2.8 mm, which is 0.04 mm more than the diameter of a 6 mm2 cable. I only found that out yesterday, but now I know.

At the time I did not care about voltage drop, in fact, never heard of it, since I am not an electrician and I am not interested in that. When I want to know which size cable I need to use I ask a specialist, an electrician or a supplier and what they tell me is what I go with. I expect people to know their job and i am not into second guessing specialists. Perhaps i should have done that, but in that case I may as well do the whole installation myself and I simply did not have the time to do that.

What I did not expect is that a reputable company, like Victron, builds a piece of equipment which functions perfectly fine, but has a flawed design when it comes to connections. Absolutely nowhere in the user manual does it say that the design is aimed at the US market, nor does it give alternatives or guidance in case certain parts are not available.

Victron is sold in DIY, chandlers, camping shops, websites and absolutely nobody will tell you that ONLY authorized installers need to install it or that you have to follow a course on Youtube, electricians school before you are allowed to install the equipment. Perhaps it will say that on page 102 of a downloadable manual, but most people won't get that far.

In Europe Mastervolt has a pretty bad name, it is known as unreliable and prone to failures. Victron on the other hand has a reputation as top of the line with good service. All specialists will advise Victron over Mastervolt.

Is it weird that a customer expects a design of a connection block to be fail safe ? Is it weird that a customer trusts a company, which has been trained by Victron, to be able to do a correct installation ? Or have we arrived at the point where we need to personally check all the work that has been done. In total I paid close to 60.000 euro for all the equipment, batteries, cables and installation. I decided to use the absolute best of the best quality cables, used by Feadship, Lurssen etc, up to the highest class specifications, since I did not want any risk of fires due to cables falling apart as a result of high temperatures. In other words, nowhere did I try to save money by using sub standard cables or equipment.

The only thing I did not expect was a flawed design of connection block in a solar panel controller. I could have even used the solar panels without the controllers, but in order to optimize the output I opted for MPPT controllers.

And when did I find out the design was flawed ?

I found out because the design caused the connection to come loose and subsequently start a fire. Not once, but twice.

Already after the first fire I asked myself if it was normal that I had to retighten the screws every single month after paying 60.000 euro for a complete new electrical system onboard. Since when is that acceptable ?

And now, after I contacted Victron I am told that the specs are aimed at the US market and not at the EU market ? Nobody in Victron apparently thought of the consequences of that choice. When customers in Europe cannot find the right size cable Victron simply blames the customer ? That is the normal way to go ?

And when that same customer digs a bit deeper he simply gets an e-mail stating that,

Het ontwerp is gebaseerd op de AWG maar en bij gebruik van de juiste aderhuls/kabelschoen is de verbinding goed.

Het is niet dat u 1 van de weinigen of eersten bent die deze MPPT gebruiken, en dat gaat vrijwel altijd goed tenzij installatie instructies niet gevolgd worden..

translated:

The design is based on the AWG, but when used with the correct ferrule the connection is good.

It is not that you are 1 of the few or first that uses this MPPT and this almost always goes well, unless the installation instructions are not followed.

In other words, if you use the wrong cable and ferrule you will have a fire hazard. I have asked Victron multiple times now what should be done if the correct cable and ferrule cannot not be sourced. I am still waiting for an answer, they refuse to answer that question.

Victron even went so far as to claim that MPPT controllers are used in aircraft. I have absolutely no clue in which aircraft solar panel controllers are being used, still waiting for that answer. Boeing 737 Max perhaps ?

In all it sounds to me that Victron knows very well the design of the connection block is inadequate in certain situations, but they have no interest in making it safe in all situations. They clearly accept a non 100 % safe situation. Why ? I have no idea, but I have been twice on the receiving end of a situation where the connection block failed to keep the cable tight.

Should a customer expect that a cable connection is safe ?

Should a customer expect and accept that using a one size larger cable will instantly result in a fire hazard ?

Has Victron warned their installers that a fire hazard will occur if the exact prescribed cable is not used ?

Should Victron warn the customers explicitly that only one size cable can be used ?

Does Victron have an obligation to make these cables and ferrules available in countries where this particular cable is non standard ?

So many questions that you and I differ in. I look at this situation from the position of an end user. I should not be the one who has to check the work of electricians and check if the specifications, prescribed by Victron, can be matched in the country where I want to install the equipment.

If the band width is so narrow to me there is only one conclusion: this equipment should not be sold in countries where the prescribed installation material cannot be guaranteed. And that will take all of Europe immediately out of the equation.