Bkay

Guru

- Joined

- Aug 8, 2018

- Messages

- 580

- Location

- United States

- Vessel Name

- Wingspan

- Vessel Make

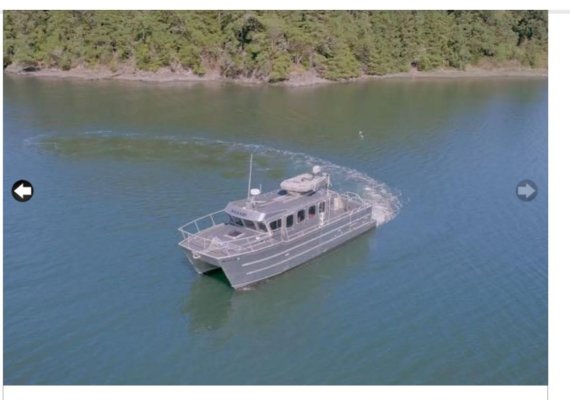

- Aluminum Catamaran

Some very tangible progress! There are now two engines with reverse gear sitting in the shop! I grew up working on John Deere tractor engines and these are the first two JD's I've ever owned.

As much as I hated working on his engines as a kid, I'm sure my dad would be amused to see me buy two of 'em.

As much as I hated working on his engines as a kid, I'm sure my dad would be amused to see me buy two of 'em.