Bkay

Guru

- Joined

- Aug 8, 2018

- Messages

- 580

- Location

- United States

- Vessel Name

- Wingspan

- Vessel Make

- Aluminum Catamaran

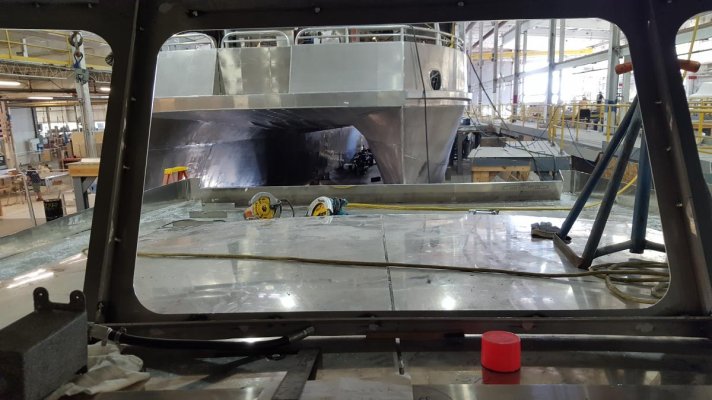

Here's a few more shots from Friday.

The first shot is port tank room looking forward into the head. Second shot is port tank room looking aft to the WT bulkhead. And third shot is starboard tank room looking forward into the berth.

The first shot is port tank room looking forward into the head. Second shot is port tank room looking aft to the WT bulkhead. And third shot is starboard tank room looking forward into the berth.