Bongi

Veteran Member

- Joined

- Dec 6, 2021

- Messages

- 98

- Vessel Name

- Scatterlings

- Vessel Make

- Grand Banks 42C

Folks, this video by John over at Oxford Yacht Agency scares me a little as l consider how we can treat our water tanks to keep the water potable.

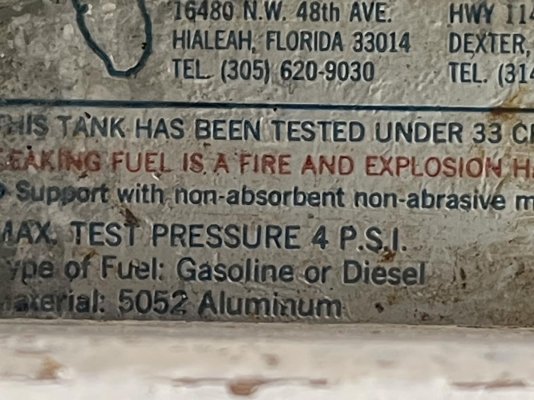

To be fair… I think our 1986 GB42C has steel water tanks and John was showing an aluminum tank from a more recent model GB36.

What should I be concerned about when adding a water sanitizing chemical, like a little bleach for example, to prevent contamination of our tank water?

I know the mild steel tanks should also be well cared for…lest they start corroding from the inside.

To be fair… I think our 1986 GB42C has steel water tanks and John was showing an aluminum tank from a more recent model GB36.

What should I be concerned about when adding a water sanitizing chemical, like a little bleach for example, to prevent contamination of our tank water?

I know the mild steel tanks should also be well cared for…lest they start corroding from the inside.