tugboater

Veteran Member

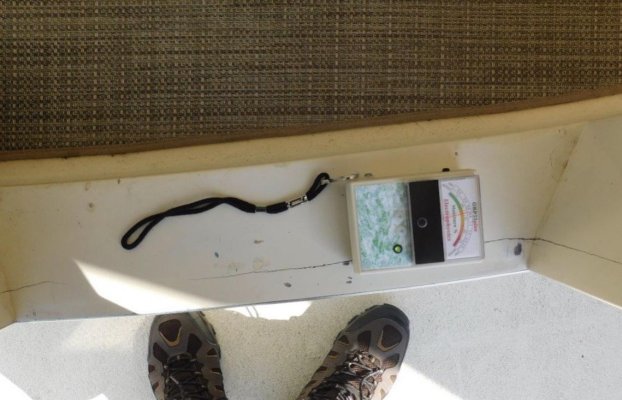

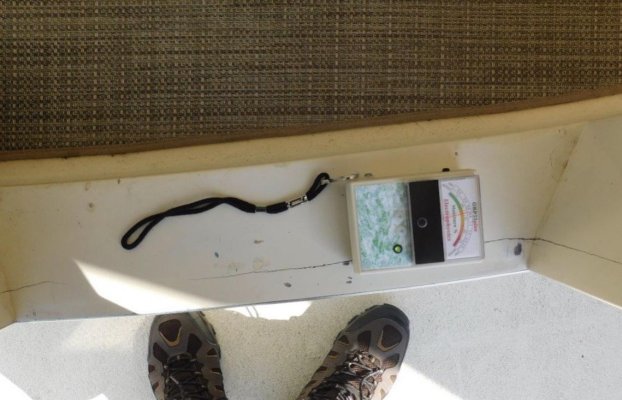

Curious how to go about the "best practice" fix for this (see photos)? Assuming excavate & fill? If so, what materials? I'm new to fiberglass. Google offers up so many solutions...would love to hear what some of you forum folks have done & what methods/materials/fillers have achieved the best results. Surveyor says moisture content appears to be negligible...seems probable because the boat has been in a covered slip and rarely used the last few years. Would like to do this once the right way.

Also, is there a fiberglass repair "bible" out there that is widely used?

Thanks!

Also, is there a fiberglass repair "bible" out there that is widely used?

Thanks!

Last edited: