An alarm is a good idea since it will grab your attention NOW. A guage will not even if you check it often. Too often our attention is occupied by other duties that are equally important so a guage change can be missed. Even boredom can take its toll on your attention no matter how good your intentions are.

Having two guages, one at each of the two helms is good too but use an alarm also. It could save your engine. Check the lowest oil pressure the guage shows and get a switch with a trip point just a little under to avoid nuisance alarms.

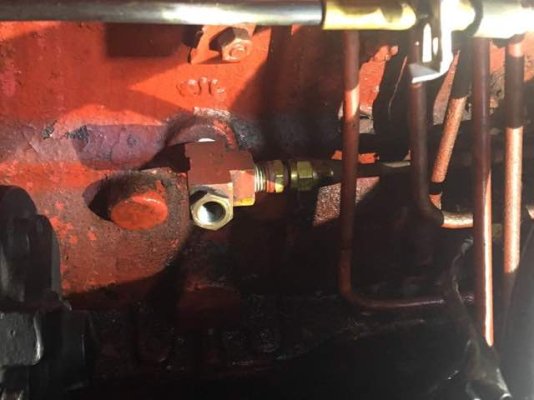

I'll mention that for the first TEE , the one that actually screws into the engine block, use a STEEL HYDRAULIC fitting. They are MUCH stronger and more vibration resistant than the brass fittings the picture shows. Then the second TEE could be brass as it only has its own and the sender weight to hold. A forged brass fitting is much stronger than the extruded brass fittings in the photo.

Use a sealer for the threads. You won't have to wind it in as tight as the sealer will seal instead of using the metal/metal contact to effect the seal. It will still make metal/metal but you don't need to crush the metals together.

Check with a multimeter, ohms, if you are questioning the grounding. Or purchase senders that have an isolated or floating ground. Just means you must then run a dedicated ground wire to a convenient spot/bolt.

I also think Hopcar has a point about a crack developing in that first TEE since it was leak free untill recently.