healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Disclaimer: The following project is to enhance the repair, convenience, maintenance and accessibility on a Kadey Krogen Manatee only. It deals with the modification of materials and construction methods that may be specific to this boat. These procedures may not apply (or even make sense) for designs other than the KK Manatee, and there may even be exceptions within the 99 unit Manatee build run where bulkhead locations have been altered by the builder or subsequent owners.

Krogen Manatees are great boats and respond well to modifications that enhance its live-ability and convenience. If you are an owner under 5' 6" or are a part-time contortionist, there is probably nothing you would change about the boat. But if you are over 6 ft. and big and old and stiff like I am, you need help. This project share is about how to relocate a standard Northern Lights 4.5 or 5.0 Genset to a new location under the veranda. It isn't cheap to do, but if you're like I am and love the boat's many advantages, spending the money for this improvement may be the singular reason to "keep" the boat instead of looking for something with the proverbial "stand-up" engine and machinery space.

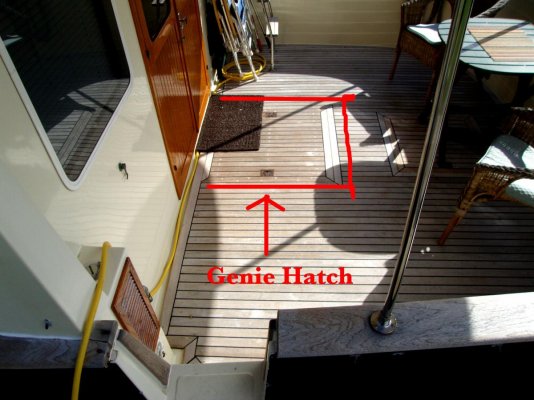

A year ago another Manatee owner brought his boat into the Krogen Brokerage to sell. When I saw the second hatch in the veranda, the owner told me it was where he had his generator. I nearly fell overboard. For the first time, could there possibly be a below-deck alternative for mounting a Genset??!!

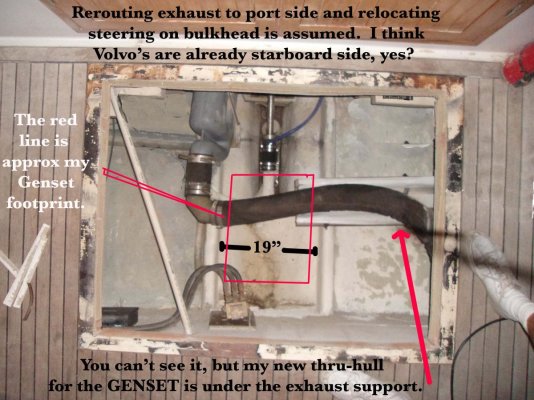

The unit was a 5.0 Onan. After some quick measuring, I learned that it was about 1.5" longer and 1.5" taller than my own Northern Lights unit. Drain pan width was the same 17", and fit snugly between the stringers (19" apart). According to the Manatee database, the boat was hull # 49, and that the 2nd owner (there were four listed) had installed a 2nd lazarette hatch (no mention of a genset). My guess is that the hatch was done for storage only, and a subsequent owner probably looked at it and figured he could throw a genset in there, which he did. BUT, it's a pretty tight hatch.

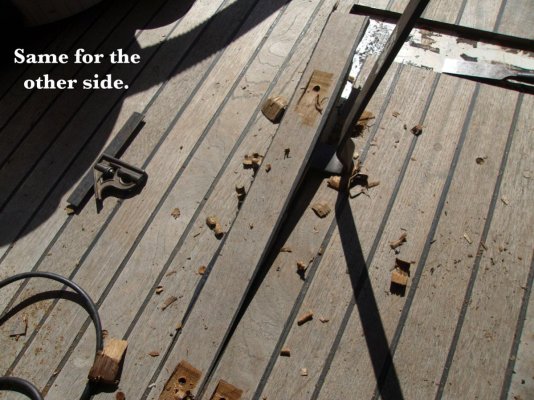

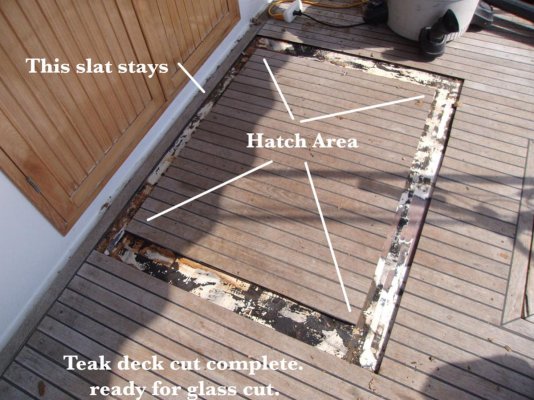

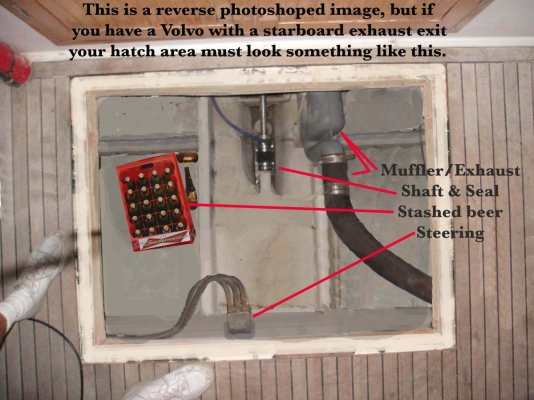

My first thought was "could we make it bigger". Yeah, we can, and I'm going to show you how to make your own generator space that you can stand on either side (yes, even the non service side) and work on the unit. The project is nearing completion and looks good. Location of the water-lift muffler is a little more difficult on my boat due to the Yanmar refit (both lift mufflers on port side) but those with original Volvos or even Perkins should have an easier routing. There were some problems with the Onan installation that I've figured a way around. For the life of me, I can't figure out why Krogen didn't offer this location or at least the 2nd hatch option for storage (lots of new, accessible space). Given the immersion data on the boat, the extra 375 lbs. located aft is no issue, especially since batteries and other devices now have new space below the galley to offset any CG change.

Relocating the genset from below the galley is like moving every system in that machinery space. Immediately, head systems and plumbing, fresh water pump and plumbing, charger/inverter, hot water heater, waste holding tank and vent, and various electrical & fuel tank access becomes so much simpler. Plop down a decent sized piece of plywood and go to work cleaning up things that you couldn't even see before. I can actually change-out my holding tank vent with ease. Before, I couldn't even see my holding tank.

More to follow, but below are the photos of why I started the project and two shots of the tight Onan installation on Hull # 49.

Krogen Manatees are great boats and respond well to modifications that enhance its live-ability and convenience. If you are an owner under 5' 6" or are a part-time contortionist, there is probably nothing you would change about the boat. But if you are over 6 ft. and big and old and stiff like I am, you need help. This project share is about how to relocate a standard Northern Lights 4.5 or 5.0 Genset to a new location under the veranda. It isn't cheap to do, but if you're like I am and love the boat's many advantages, spending the money for this improvement may be the singular reason to "keep" the boat instead of looking for something with the proverbial "stand-up" engine and machinery space.

A year ago another Manatee owner brought his boat into the Krogen Brokerage to sell. When I saw the second hatch in the veranda, the owner told me it was where he had his generator. I nearly fell overboard. For the first time, could there possibly be a below-deck alternative for mounting a Genset??!!

The unit was a 5.0 Onan. After some quick measuring, I learned that it was about 1.5" longer and 1.5" taller than my own Northern Lights unit. Drain pan width was the same 17", and fit snugly between the stringers (19" apart). According to the Manatee database, the boat was hull # 49, and that the 2nd owner (there were four listed) had installed a 2nd lazarette hatch (no mention of a genset). My guess is that the hatch was done for storage only, and a subsequent owner probably looked at it and figured he could throw a genset in there, which he did. BUT, it's a pretty tight hatch.

My first thought was "could we make it bigger". Yeah, we can, and I'm going to show you how to make your own generator space that you can stand on either side (yes, even the non service side) and work on the unit. The project is nearing completion and looks good. Location of the water-lift muffler is a little more difficult on my boat due to the Yanmar refit (both lift mufflers on port side) but those with original Volvos or even Perkins should have an easier routing. There were some problems with the Onan installation that I've figured a way around. For the life of me, I can't figure out why Krogen didn't offer this location or at least the 2nd hatch option for storage (lots of new, accessible space). Given the immersion data on the boat, the extra 375 lbs. located aft is no issue, especially since batteries and other devices now have new space below the galley to offset any CG change.

Relocating the genset from below the galley is like moving every system in that machinery space. Immediately, head systems and plumbing, fresh water pump and plumbing, charger/inverter, hot water heater, waste holding tank and vent, and various electrical & fuel tank access becomes so much simpler. Plop down a decent sized piece of plywood and go to work cleaning up things that you couldn't even see before. I can actually change-out my holding tank vent with ease. Before, I couldn't even see my holding tank.

More to follow, but below are the photos of why I started the project and two shots of the tight Onan installation on Hull # 49.