SILENTKNIGHT

Senior Member

- Joined

- Oct 19, 2018

- Messages

- 187

- Location

- United States

- Vessel Name

- STELLA DI MARE

- Vessel Make

- 2006 MAINSHIP 34T

2006 Mainship 34T

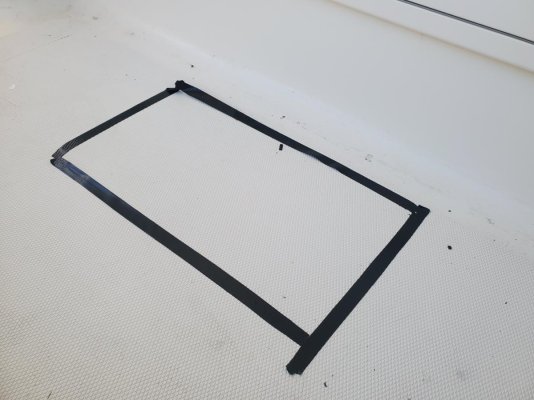

so i noticed today the aft deck flooring( i marked in black tape) right outside the salon doors , " Spongy squeaking " I did the tap test and its got the "hollow sound."

Wheere could water intrusion occur?

I went down below and pulled down the headliner in the engine room... its soft.

Please tell me what steps i can take to fix, correct this section... Assuming i should do this from below ?

so i noticed today the aft deck flooring( i marked in black tape) right outside the salon doors , " Spongy squeaking " I did the tap test and its got the "hollow sound."

Wheere could water intrusion occur?

I went down below and pulled down the headliner in the engine room... its soft.

Please tell me what steps i can take to fix, correct this section... Assuming i should do this from below ?