Without a schematic or sketch, very difficult to follow - not sure what is meant by ER (engine room?) and how that aligns to cabling. Sounds like you cabled the inverter into a positive that is shared, which is a bad idea given the load - your inverter can pull up to100-amps. There is no way your electronics circuit was sized with this type of load in mind. But maybe I have this wrong.

The inverter positive really needs to run to the battery with dedicated breaker and as short a cable run as possible. Much easier and affordable to make long runs of 10-amp 120VAC wire runs (14-guage) than 100-amp 12VDC cable runs (1-awg and 10x the price)

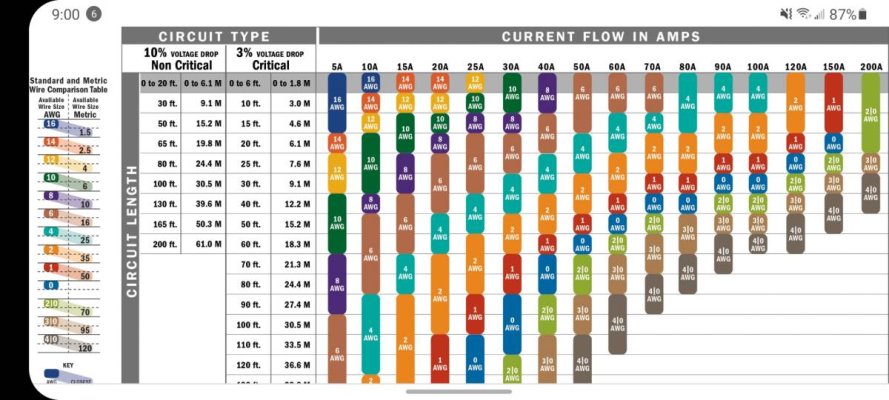

If you're asking if you can run a short negative to a convenient ground but run a long positive to the batteries, answer is yes - but the ground really needs to be a meaty ground. If the ground is then cabled further to the battery, then that total load and length needs to be factored too. The attached Blue Sea cable size chart should be read as the entire circuit length - positive plus negative cable runs (25 feet in this example). If you are running 5-feet of negative and 20-feet of positive for your 1100w inverter (90 amps 12v), you need 1-awg cable at a minimum for 3% loss. There should be a dedicated breaker of 150-amp as near the battery as possible. As an observation, 1100w inverter is pretty small these days and you may want to upgrade. For this example, I'd run 2/0 awg despite the expense to avoid having to rerun larger cable down the road. Breaker should sized for current inverter, not future though.

Finally, no mention about your batteries. I'd guess that well over half the issues I see with mid-sized DIY inverters trace to undersize or old FLA battery banks. There is a surprising amount of voltage drop across the terminals in high draw applications such as an inverter, which is why it's important to eliminate voltage drop across the cables and size them properly. The fact you are tripping a shared breaker tells me you are overloading the breaker. However, it's not unheard of for electronics to shut down due to undervoltage when an oversized inverter load kicks-in and drops system voltage. LiFePO4 batteries can discharge without nearly as much voltage drop which is one of the many benefits compared to FLA.

Good luck.

Peter

View attachment 124815

Thank you Peter and Soo Valley.

Sorry to be so confusing, even in the thread title. I will try to be more clear.

1. Yes, the coffee pot is plugged directly into the inverter. In the instances of the tripping breaker it is the only load plugged into the inverter.

2. My house bank is 4 6V lead acid batteries which total 440 AH. They are two years old and in good condition, according to my state of charge monitor. I am careful to keep up with water etc.

3. Yes, by ER, I meant engine room. The Mainship 400 has two DC panels, the first panel is next to the fridge in the main cabin. It shares a cabinet with the fridge and you have to pull the fridge out in order to gain access to the inside of the cabinet. There is a substantial positive cable that leads from the battery switch in the engine room up into the fridge cabinet and then to a terminal post. The positive lead from the breaker panel in the cabin is attached to this post. There is also a substantial ground cable that comes from a buss bar in the engine room and leads to a buss in the cabinet behind the fridge.

The second DC panel is in the ER near the battery switches. Certain larger loads, like the windlass are on this second, ER, panel including a breaker that is labeled "electronics." But I strongly suspect that the electronics breaker shares some other various loads as well. It uses a substantial cable as well, I think it is 2/0, and leads to a terminal post under the lower helm. There is also a 2/0 ground cable that leads to terminal post under the lower helm next to the positive post.

Currently, I have DC cables from my inverter wired to the two posts under the lower helm. I am considering moving the inverter into the fridge cabinet. It would be easiest to wire the DC cables from the inverter to the positive and negative posts that are already in the cabinet, but I am afraid I would face the same issue of overloading that circuit when I put a heavy load on the inverter.

So here are my questions.

1. When I put a heavy AC load on the inverter, like the coffee pot, does it increase the DC load as well? Do you think that is causing an overcurrent situation that is tripping the electronics breaker in my current set up?

2. If I run a new positive cable directly to the battery, can I use the negative buss bar that is already in the fridge cabinet for the negative cable? Or should I run a new, longer negative cable to the main negative buss bar in the engine room? If I go with the shorter negative cable run, how do I size the shorter negative cable? Same size as the longer positive cable?

I think you answered this question in your third paragraph, Peter. But since there are other loads on the convenient DC buss, do I calculate all of the loads on that buss? How would I do that?

3. I'd like to be able to shut down the inverter circuit when I turn off the main battery switch, so I'd prefer to wire the positive cable to the switch post rather than directly to the battery. Do you see an issue with this?

Thanks,

Doug