"finger tight is about 1.2 to 1.7 foot-pounds"

so 1.5 to 3.5 could be in ft lbs unit

You said the guidelines are to tighten to 30 in-lbs which equals 2.5 ft-lbs.

12 in-lbs = 1 ft-lbs

"finger tight is about 1.2 to 1.7 foot-pounds"

so 1.5 to 3.5 could be in ft lbs unit

is this shut-off valves the right link?

why add the 1/4" MIP plug? without a plug it should not leak.

what sealant to use on the threads? yellow teflon and/or loctite 592?

The Racor part number is RK19492 and it includes the stopper nut.

-Chris

You said the guidelines are to tighten to 30 in-lbs which equals 2.5 ft-lbs.

12 in-lbs = 1 ft-lbs

yes, the manual says to tighten to 30 in-lbs

in-lbs is a very low torque, a wrench can easily overtighten. Do people generally use an in-lbs torque wrench to get it right?

It's FG500. Those filters were installed at least 10 years ago. They are still working in order to provide filtered fuel to the engine and genset. I don't know the service life. As long as it works I'm not pressed to make any changes

You have the same Racor filters as I have. First: service life. Mine were installed when my boat was built, in 1980. The last time I changed my filters, was only three or four years ago, and at that time, as always, I removed the whole assembly from the wall and disassembled it. I found it in exactly the same condition as on its last disassembly, that is, that it would benefit from being cleaned, which I do each time, but needed nothing more than a renewal of the filter and its gasket and the O ring on the T handle.

Secondly, servicing:

Removal and disassembly and re-installation with the new filter, gasket and O ring takes no more than a few minutes and requires no special tools. You will need only a couple of wrenches to undo the supply and discharge lines, a screwdriver to remove the mounting screws and a different (Phillips) screwdriver to disassemble the Racor unit.. If you have a bucket, do your disassembly there, so you can keep the area where you do the disassembly clear of fuel. Log your servicing, then you will know how long yours will last before you see anything in the bowl.

On re-reading your post, I am not sure you are referring to the service life of the whole Racor unit, or just the replaceable filters and O rings. I have addressed the unit above. The filters, here in SW BC, Canada where we get good, clean fuel from most vendors, my Racors typically last 4 or more years. My on-engine secondaries last 10 to 12 years. The clear bowl permits quick inspection every time I am in the Engine Room.

You will see many discussion of this nature on this site and others, but we live in a fast changing world, where the push for cleaner air has pushed fuel suppliers to far better filtering in recent times, in order to achieve that. As a result, our much cleaner fuel has resulted in much better service life for all parts of the fuel system.

Easy to replace bowl. Aftermarket available.

A metallic plug, or the brass UL Marine (it only turns through 90 degrees and uses no springs to maintain tension and liquid tight seal, not all valves are alike) valve and heat shield are required for ABYC compliance. I'm disappointed that a surveyor would have suggested a catch bowl, no amount of leaking fuel is acceptable. Or, did he mean you needed the heat shield (bowl) as well?

More here https://stevedmarineconsulting.com/...bolt-a-cigarette-lighter-and-distracted-work/

As far as the link, yes as per their web site.

It’s a 90 degree valve. Without the plug and you inadvertently move/bump it a couple of degrees your leak will be a lot worse than what you have now. You can buy 5 for $7 on Amazon. We cruised 60k plus miles. I’m into stress reduction. One less potential leak point.

I use RectorSeal #5.

Edit: it’s probably spell check on your end but they are npt threads.

The plug is installed into the valve to prevent an inadvertent leak, an especially serious issue for tanks that bottom feed and the filter is below the level of fuel in the tank, as the filter is subject to the head of pressure created by the fuel column in the tank.

I had a case of a tech leaving an engine room on a vessel on a Friday afternoon, the vessel was hauled and inside our paint bay, he thinks his tool bag dragged over the valve and opened it, on Monday we returned to find 70 gallons of fuel in the bilge. Thankfully, the electrical system was being worked on so the bilge pumps were inactive, it would have been a disaster.

If you apply a wrap of Teflon tape to the drain plug, you can screw it in by hand, it won't leak and it will be easily removable without tools later. I have nothing against a plastic drain plug, but technically it does violate the ABYC Standard for flame resistance. If the valve is opened and the plug is the only thing from keeping fuel from leaking, and there is a fire, the plug will melt and discharge fuel.

Marco,

I’m freaking in love with the bucket idea. Awesomely simple. It’s my next thing to do next filter changes.

But…. How did you mount them? I want to get any other parts and pieces needed.

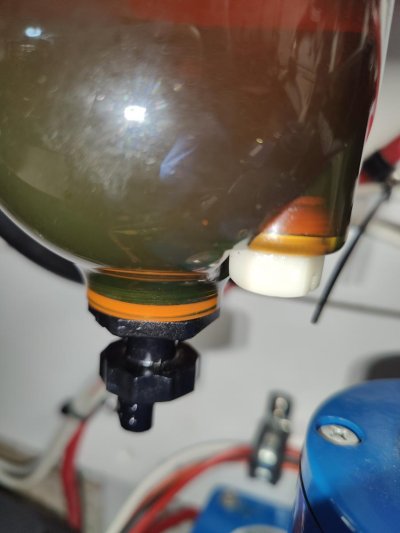

Thanks for the photo.

Do not use an o ring. The valve has npt threads.

I wouldn’t use a nylon plug since the manufacturer specs brass plus nylon doesn’t have a place in fuel systems imho.

Thanks for the details.

what was the outcome of that diesel leak? an insurance claim/lawsuit?

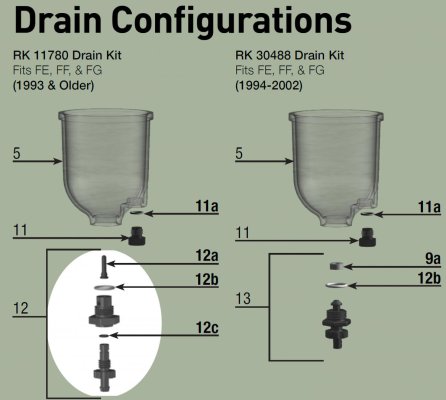

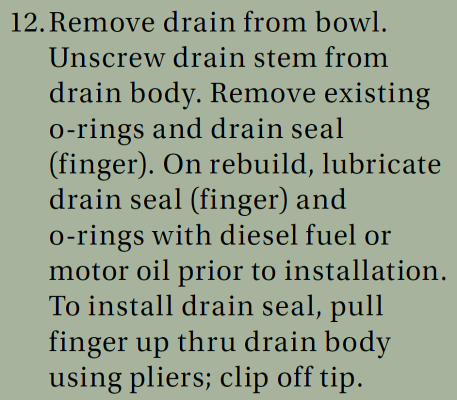

As you said, unscrew the hex head. It has standard threads.

is this shut-off valves the right link?

why add the 1/4" MIP plug? without a plug it should not leak.

what sealant to use on the threads? yellow teflon and/or loctite 592?

You can purchase UL LIsted valves generically for about half the price of the Racor units, the manufacturer is Kantleak, McMaster has them as do others.

Easy to replace bowl. Aftermarket available.