TheLake

Veteran Member

- Joined

- Oct 16, 2021

- Messages

- 51

- Vessel Name

- The Lake

- Vessel Make

- 42' CHB Tricabin

Hi all,

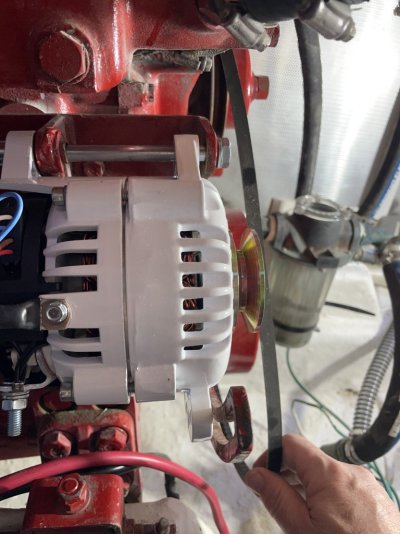

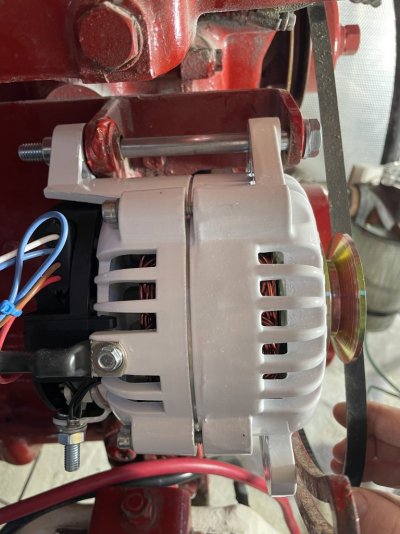

As part of my engine rewiring project I am replacing my old alternators with new Balmar 60 - 100amp - Single V alternators.

I plan on having one go to the house bank through my Lynx Distributor. The other will go to a Victron Argofet where it will charge both my starter batteries.

I am looking at the mount for the alternators, and it seems like it doesn't quite fit. So I am hoping to get some advise.

If I mount it in the most logical format, there is about a 1/4" gap from one of the mounting legs to the mount. I suppose that I could put some washers in to fill the gap. But with this placement, the belt does not line up. Note that the shaft has two v-belt slots. If I did this mounting, maybe I could get one belt on the outer slot for the water pump, and then use the inner slot for the alternator??????

I think my other option is to just get a new mounting bracket machined to fit. It seems like it is just a plate that is mounted with three bolts onto the engine.

Thoughts?

Has anyone else done this?

Chris

As part of my engine rewiring project I am replacing my old alternators with new Balmar 60 - 100amp - Single V alternators.

I plan on having one go to the house bank through my Lynx Distributor. The other will go to a Victron Argofet where it will charge both my starter batteries.

I am looking at the mount for the alternators, and it seems like it doesn't quite fit. So I am hoping to get some advise.

If I mount it in the most logical format, there is about a 1/4" gap from one of the mounting legs to the mount. I suppose that I could put some washers in to fill the gap. But with this placement, the belt does not line up. Note that the shaft has two v-belt slots. If I did this mounting, maybe I could get one belt on the outer slot for the water pump, and then use the inner slot for the alternator??????

I think my other option is to just get a new mounting bracket machined to fit. It seems like it is just a plate that is mounted with three bolts onto the engine.

Thoughts?

Has anyone else done this?

Chris