Hippocampus

Guru

- Joined

- Jul 27, 2020

- Messages

- 4,182

- Location

- Plymouth

- Vessel Name

- Hippocampus

- Vessel Make

- Nordic Tug 42

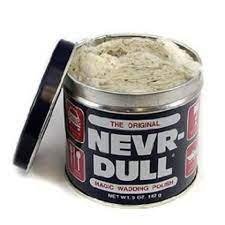

Splashing beginning of next week so doing all the stainless that’s more difficult to reach when in the water. And I HATE stainless. This evening all my fingers hurt. Getting into cracks and crevices, between pieces and dong welds to get out every last spot is so time consuming. Have used every product out there but end up going back to the collinite ones as believe you get a longer interval between need to do t again.

What do you use? Will you share your tricks of the trade?

What do you use? Will you share your tricks of the trade?