I have explained the mathematical calculations once before, you can find it in this topic.

Our average depth for the hook this year in B.C. and SEAK was 40 to 60ft. There were times we anchored deeper 80-120ft. 3:1 worked most of the time. Never dragged even in 45kt winds. We have a 77lb rockna with 550ft of chain. It always sticks. Sometimes, you had to back up a bit to allow it to...

www.trawlerforum.com

What it comes down to is calculating your wind surface, which is usually the frontal part of the boat, from sea level to the highest point. That will give you a certain number of square meters (or square feet if you want to calculated like that.

Then you calculate the wind force at which the boat should still be safe. If you never encounter winds above 6 Bft on anchor there is no reason to calculate for 12 Bft. If you do encounter stronger winds or wind gusts obviously you will need to calculate with those windspeeds.

Usually the winds are given at 10 mtrs high, so winds at sea level are around 70 % of that on the 10 mtr level. However, if you find yourself in open sea, with not a lot of protection, then calculating the full wind speed is the best option.

4 Bft = 21.5 N/m2

5 Bft = 40 N/m2

6 Bft = 70 N/m2

7 Bft = 110 N/m2

8 Bft = 151 N/m2

9 Bft = 224 N/m2

10 Bft = 290 N/m2

Again, if you feel comfortable calculating with 70 % of that then feel free to do so.

The forces you read above now need to be multiplied by the total square meters of the frontal surface of the boat.

So, let's say frontal surface is 15 m2 then at 8 Bft you would encounter a force of 2250 N on the boat.

In order to avoid dragging you would need to counter that force with a minimum of 2250 N via holding power of the anchor plus chain.

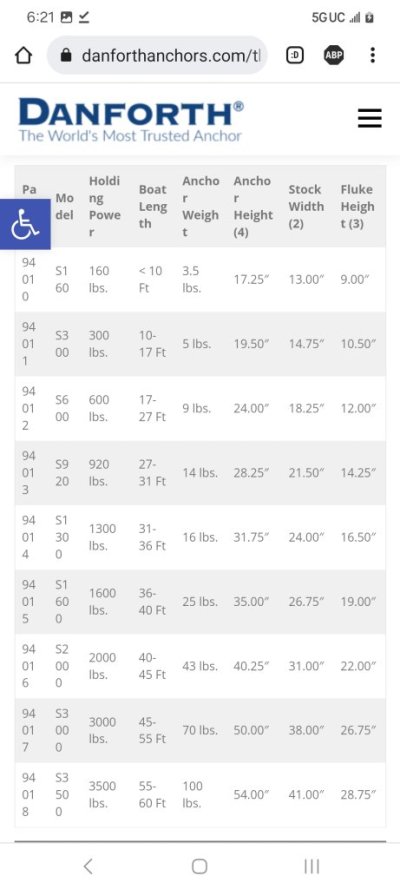

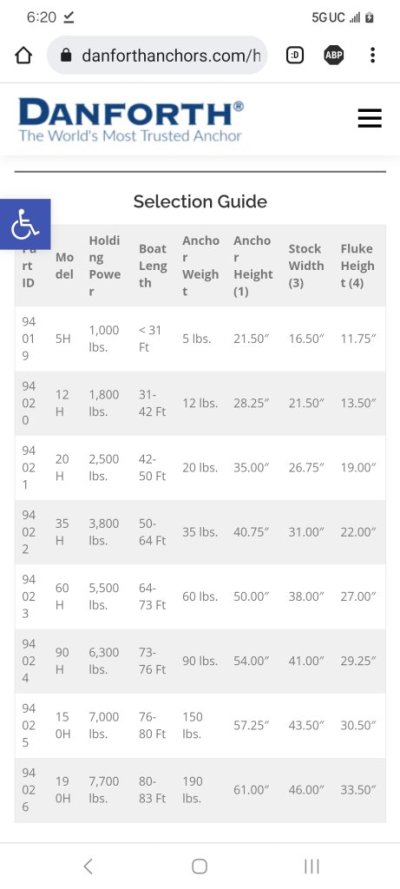

The holding power for each type of sea bed should be provided by the anchor manufacturer, so that one is a given.

As for the anchor chain, you can find the weight per meter for every diameter of anchor chain real easy, but otherwise the supplier of the chain should be able to provide that.

The weight of the chain in kilogram is multiplied by 10 to get to Newton and to that you add the weight of the anchor, also in kilograms, multiplied by 10.

E.g. my chain is 4 kg per meter, my anchor is 50 kg. So at 50 meters I have 250 kg in total in the water, for a total of 2500 N and that is without the holding power of the anchor.

In theory this should be enough to not start dragging at 8 Bft however we have to take the depth of the water into consideration and the result that has on the angle of the chain (and anchor shank) to the sea bed. Because, as soon as the angle of the shank reaches 25 degrees off the sea bed, the anchor has zero holding power, other than the weight of the total anchor plus chain.

Large vessels don't rely on the holding power of the anchor, they basically anchor based on the weight of the chain and anchor. Smaller vessels need the holding power of the anchor to ensure safe anchoring, since many boats don't have heavy chains. In fact, many boats have undersized chains and anchors, making calculating the required holding power very important.

Based on the above you can decide at which wind speed you still want to feel safe and comfortable. I know that nobody, in his right mind, is going to anchor in 10 Bft, but a heavy thunderstorm or squal line can bring winds of 60 kts. Even when that lasts for only 15 min I think that all of us will want to be safe.

So, instead of guessing how heavy the anchor or how thick the chain should be you can actually calculate what you need in which situation.

Of course there are other considerations, such as current, wave height, tides etc, but also those are mathematical calculations which will lead to a solution.

Hope it helps you.