CharlieO.

Guru

- Joined

- Sep 21, 2020

- Messages

- 1,749

- Location

- Lake Champlain Vermont, USA

- Vessel Name

- Luna C.

- Vessel Make

- 1977 Marine Trader 34DC

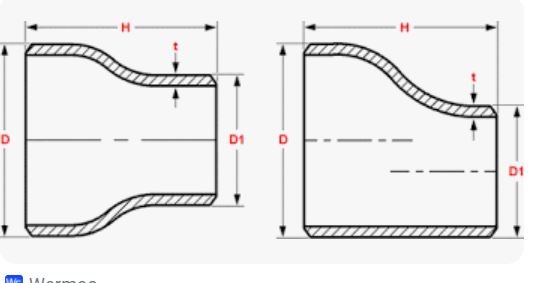

What is this part that is between the exhaust hose and transom exit? I thought it was a check valve it appears to have some sort of baffles inside on the outer perimeter.

Is it common to have this sort of splice in the exhaust hose? It looks like a four inch exhaust hose was used as a sleeve to couple the 3 1/2 inch exhaust hose together. Everything thing was double clamped .

I am planning on replacing the exhaust hose so just want to be sure I do it correctly.

Best place to source exhaust hose? Any tips on install and preferred hose?

Is it common to have this sort of splice in the exhaust hose? It looks like a four inch exhaust hose was used as a sleeve to couple the 3 1/2 inch exhaust hose together. Everything thing was double clamped .

I am planning on replacing the exhaust hose so just want to be sure I do it correctly.

Best place to source exhaust hose? Any tips on install and preferred hose?

Project creep. To get to to the swim platform hardware I needed to remove to the water tanks, to remove the water tanks I had to remove my rudder so I could pull the rudder shaft out. While I am in there the only thing else is the exhaust and it runs outboard of the port water tank, this is the only time I will have this kind of access. Hard piping from the transom to at least thru the aft bulkhead seems appealing though. My only concern with that is that would put my muffler under the port bunk.

Project creep. To get to to the swim platform hardware I needed to remove to the water tanks, to remove the water tanks I had to remove my rudder so I could pull the rudder shaft out. While I am in there the only thing else is the exhaust and it runs outboard of the port water tank, this is the only time I will have this kind of access. Hard piping from the transom to at least thru the aft bulkhead seems appealing though. My only concern with that is that would put my muffler under the port bunk.