Good ER ventilation is critically important. Definitely calc what you need by way of the article Craig referenced or some other means. Best to overdo it to help with heat in ER also. Poor ER ventilation is surprisingly common and can cause premature engine failure.

I have some Vetus vents, not cheap unfortunately.

Louvered Engine Room Air Vent - Vetus Denouden | Fisheries Supply

We made a dorade system for them because we lacked the depth in the hull to use the Vetus ones.

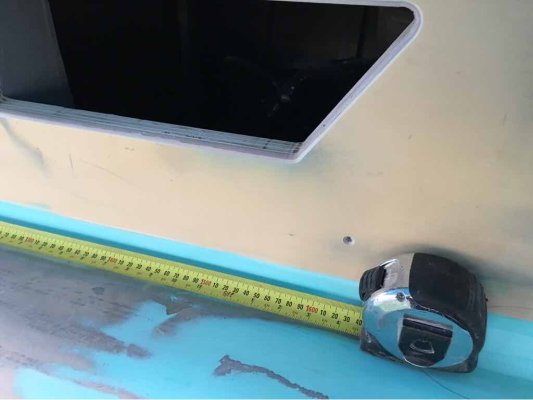

I'm using 2 x 750 cfm Delta T axial vans for the air intakes (4 intake vents all up, two on outside the hull and two on inside to walkaround deck) at the front of the ER. Then at the rear of the ER I have 2 x 350 cfm centrifugal fans ducted to the two rear ER vents for outlet.

Apart from volume, stopping rain and big waves is also a must. For the rain and spray the dorade style design in post #1 is good. But for prevention of downflooding in a roll in big seas you would ideally have air intake as high as possible and avoid the hull sides where the ER is situated. If you are able to do it, ventilation via ducts from vents high in the superstructure is ideal.

It was rain entering my ER vents that caused my black steel fuel tanks to fail, although it did take 30 years for them to start leaking.