Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,631

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

Roca wind shield wipers leaking on new to me boat. I returned to the boat after some heavy rain to find leaks. Reasonably sure it is the wipers. Found by crawling under the dash.

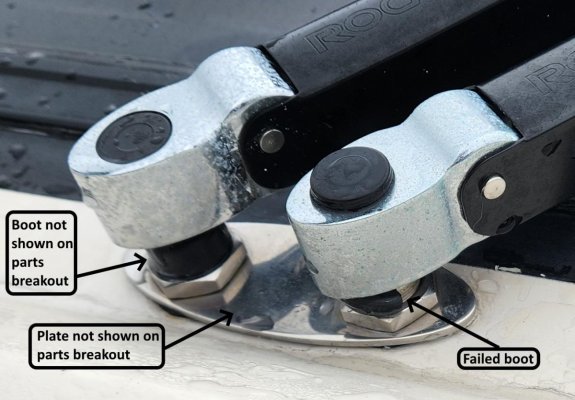

Checked the wipers and found a rubber boot torn and lock nuts loose enough to be able to wobble the spindles and the plate.

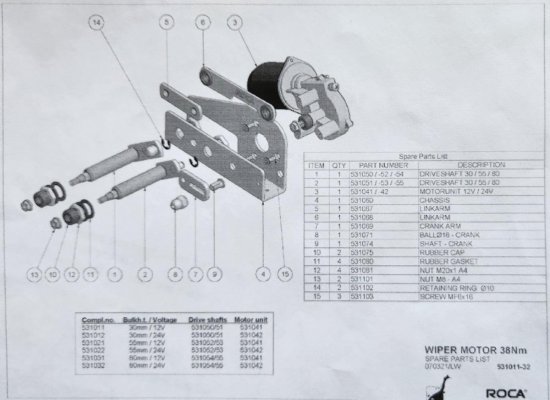

Tightened the lock nuts. Now looking for the rubber boots, not shown on the parts breakout. And some way to seal the plate, also not shown on the parts breakout.

Any and all suggestions on how to seal the plate and where to find parts most appreciated.

Checked the wipers and found a rubber boot torn and lock nuts loose enough to be able to wobble the spindles and the plate.

Tightened the lock nuts. Now looking for the rubber boots, not shown on the parts breakout. And some way to seal the plate, also not shown on the parts breakout.

Any and all suggestions on how to seal the plate and where to find parts most appreciated.