Mambo42

Guru

- Joined

- Oct 26, 2021

- Messages

- 924

- Vessel Name

- Endless Summer

- Vessel Make

- 1979 Defever 49

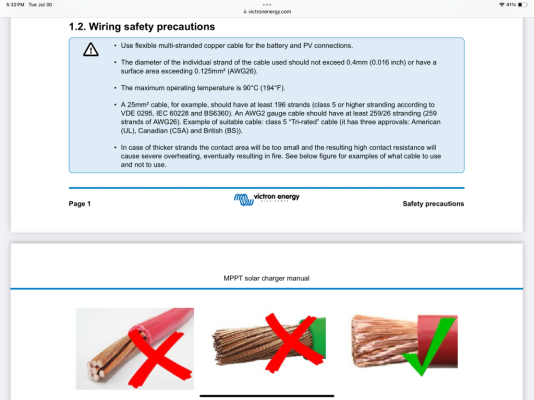

Just for your info, the wire you found would not meet the standards of Victron, so basically you have still found an incorrect cable.Where did I admit that I know nothing about Victron? I have no strong opinions or vested interests in anything Victron. You don't need to own or use a product to be able to see when someone is trashing the product for no reason other than a self serving one. It burnt up, can't be my fault, must be junk.

Same thing on the wire, Mambo42 repeatedly states that you can't get 5mm2 marine grade wire in Greece without buying a large roll holding way more than he needed.

Then when confronted with the fact that a large chandlery (among others) lists 10 gauge Ancor tinned marine wire (which by the way they call 5 mm2, 10 gauge is actually 5.26 mm2, so close enough) in multiple forms and colors on their website, that you buy in any length you want, the response changes to that they all lie all the time, none of the 10 stores has any stock ever and if you order it and pay for it first, after you wait multiple times the original delivery period, they steal your money. Really?

Do you actually think that the large chandlery is in the business of ripping it's customers? What a business model. How long do you think they will last? According to their website they have been a chandlery for 30 years. Maybe they are lying there as well or perhaps someone else is?

Call me a cynic if you want, but can't you see that the constant narrative is that everybody is wrong but Mambo42? How can that be?

On top of that, the cable is not fire retardant and that was for me an absolute must. You basically suggest that I should accept a lesser, more dangerous quality, because that is the only cable that fits..............if it can be sourced ?

In how many turns and twists do you want to get yourself before you admit that the design could (and should) have been better.

Just google for fires Victron and the world will open up for you. Victron stated that I was an exception, but in reality it happens quite a lot. Not everyone publishes it on Youtube or on a Forum, so in reality the numbers are even higher.

But according to you it is the mistake of every single person and there is nothing Victron can do to prevent it ?