Serene

Senior Member

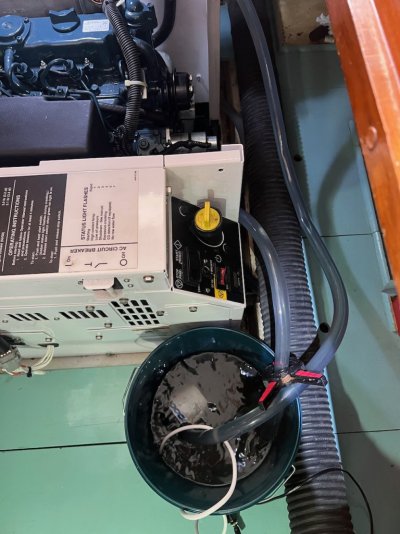

I have a Cummins Onan 6kVA Generator (MDKBJ Spec C) on my vessel, which has been layed-up for around six months while I was out of the water for my refit. I started the generator for the first time this weekend and saw what I thought was an alarmingly fast rise in coolant temperature, so shutdown the generator.

In previous usage I have checked oil pressure, the pumping of raw water out the exhaust and the coolant temperature, before adding AC loads to the generator. Typically I would add the AC loads when the temp reached around 67 degrees celsius and then I would let the generator run for the required duration. Most typically two hours to recharge batteries, pull the freezer temp down and to heat water for evening showers.

The generator started no problem, but I couldn't see raw water cooling being discharged overboard, so I monitored the temp for a period of time (3mins) to see if the muffler needed to be re-filled with raw water before discharge overboard started. I then shutdown the generator as I was concerned about an overheat situation.

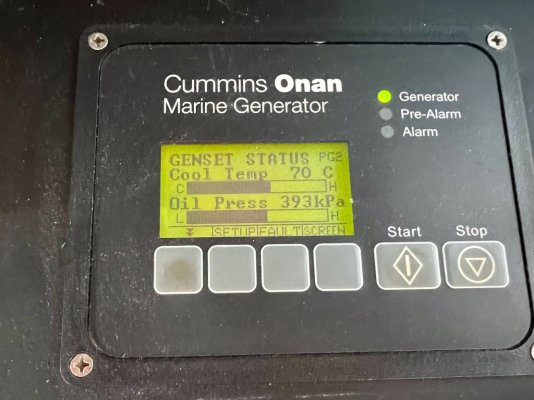

At no time did I receive any warning or errors on the control panel.

I then checked the seacock and strainer to ensure no blockages (none found) so removed the raw water pump and replaced the impeller. I was expecting to see all of the vanes stripped from the impeller, but it was surprisingly intact. Although it did have some deformity in shape. I replaced with a new impeller anyway as I already had the pump removed.

On the next start, I monitored some raw water output from the exhaust, but the temperature kept climbing up to 95 degrees celsius before I again shutdown the generator as I was worried about overheating. Again no warning or alarms.

But I cannot remember at what operating temperature the generator should stabilise, therefore I don't know if I actually have a problem or am being overly cautious.

The next step I was thinking was to replace the thermostat, in case that is frozen closed, so no coolant is being allowed to flow.

So questions;

1. What operating temp should I be seeing?

2. Am I being overly cautious given no alarms or warnings?

3. Any tips on what to do next?

In previous usage I have checked oil pressure, the pumping of raw water out the exhaust and the coolant temperature, before adding AC loads to the generator. Typically I would add the AC loads when the temp reached around 67 degrees celsius and then I would let the generator run for the required duration. Most typically two hours to recharge batteries, pull the freezer temp down and to heat water for evening showers.

The generator started no problem, but I couldn't see raw water cooling being discharged overboard, so I monitored the temp for a period of time (3mins) to see if the muffler needed to be re-filled with raw water before discharge overboard started. I then shutdown the generator as I was concerned about an overheat situation.

At no time did I receive any warning or errors on the control panel.

I then checked the seacock and strainer to ensure no blockages (none found) so removed the raw water pump and replaced the impeller. I was expecting to see all of the vanes stripped from the impeller, but it was surprisingly intact. Although it did have some deformity in shape. I replaced with a new impeller anyway as I already had the pump removed.

On the next start, I monitored some raw water output from the exhaust, but the temperature kept climbing up to 95 degrees celsius before I again shutdown the generator as I was worried about overheating. Again no warning or alarms.

But I cannot remember at what operating temperature the generator should stabilise, therefore I don't know if I actually have a problem or am being overly cautious.

The next step I was thinking was to replace the thermostat, in case that is frozen closed, so no coolant is being allowed to flow.

So questions;

1. What operating temp should I be seeing?

2. Am I being overly cautious given no alarms or warnings?

3. Any tips on what to do next?