The Dread Pirate Robert

Veteran Member

I want to write down what I have done to figure out why my gauges are not working so hopefully you can find something I have missed and point me in a better direction.

My engine oil pressure gauge and my transmission pressure gauge on both lower and upper helms of the starboard engine are pegging to max when the ignition is turned on. They go back to zero when the ignition is off.

I am working on the oil pressure gauge only for now.

1) I swapped the known working gauge of the port engine for the non working gauge of the starboard engine. The known working gauge on the starboard side pegged to max with ignition on.

2) I ran the port engine with the swapped non working gauge and it functioned properly.

That tells me my gauge is good.

3) I wired the sending unit from the port engine to the wire harness of the starboard engine and the starboard sending unit to the port wire harness. The gauges performed the same. Which means my sending units are ok.

4) I checked the continuity of the sending wire and there are no breaks.

5) I checked for any grounding of the sending wire and got no reading on my ohm meter.

6) I disconnected the sending wire from the starboard engine and connected the sending unit to the gauge with a new wire and the gauge still maxed out.

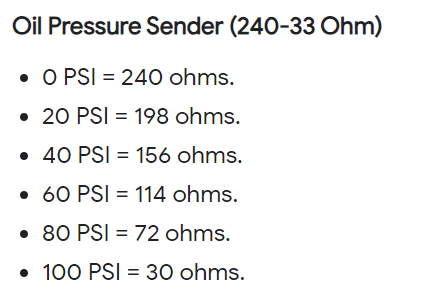

7) I connected an ohm meter to the sending unit and a ground but get no signal at all on the meter.

I hope this is not too confusing but I could really use the help in knowing if there are any other tests I can use to figure this out.

Thanks for your help.

My engine oil pressure gauge and my transmission pressure gauge on both lower and upper helms of the starboard engine are pegging to max when the ignition is turned on. They go back to zero when the ignition is off.

I am working on the oil pressure gauge only for now.

1) I swapped the known working gauge of the port engine for the non working gauge of the starboard engine. The known working gauge on the starboard side pegged to max with ignition on.

2) I ran the port engine with the swapped non working gauge and it functioned properly.

That tells me my gauge is good.

3) I wired the sending unit from the port engine to the wire harness of the starboard engine and the starboard sending unit to the port wire harness. The gauges performed the same. Which means my sending units are ok.

4) I checked the continuity of the sending wire and there are no breaks.

5) I checked for any grounding of the sending wire and got no reading on my ohm meter.

6) I disconnected the sending wire from the starboard engine and connected the sending unit to the gauge with a new wire and the gauge still maxed out.

7) I connected an ohm meter to the sending unit and a ground but get no signal at all on the meter.

I hope this is not too confusing but I could really use the help in knowing if there are any other tests I can use to figure this out.

Thanks for your help.